Introduction:

For a description of the current test heater setup in our lab, see 2006 - 2007 Heater Testing at Shawville

See Alaska Condar Tests for background information on the Condar dilution tunnel. We have one of the 4 Condars calibrated in Alaska installed here at our lab in Quebec.

Description:

Condar Setup

The Condar samples vertically through a nozzle into the top of the last flue liner. After consulting with Paul Tiegs at OMNI, we have

modified the nozzle to extend it to the centre of the flue.

The top half of the Condar is sitting on the bench. It holds the filters.

The used filters from a test are sitting to the right of the Condar:

- the main filter is black with a light coating of soot.

- the backup filter is clean, with a very small amount of tar (slightly yellow).

The Condar is powered by a vacuum hose, coming in through the wall behind the analytical balance.

The Magnehelic gauge at the top reads the flow through the Condar sampler nozzle. This is kept constant at 0.4 cfm

As the filters plug up, the vaccuum is boosted to maintain constant flow.

The vacuum motor speed is manually controlled with the Variac control directly below the Magnehelic.

The mixing barrel (dilution tunnel) portion of the Condar. The calibrated 3/8" hole at the center is the sample nozzle, which extends

to the centerline of the flue. The smaller holes draw in a fixed ratio of dilution air. This cools and dilutes the smoke, similar to what happens in the atmosphere, and allows the semi-volatiles to condense into tar droplets so that they can be collected on a filter. If the gases were hot, some of the semi-volatiles would blow through the filter uncondensed, and deposit less particulate.

To the right of the Condar is the probe for the Testo 330-2 flue gas analyzer.

To the top right is the light source for the opacity reading.

A CdS sensor is mounted on the breadboard and aimed at the light through the opening in the flue.

The metal tape covers up the damper slot.

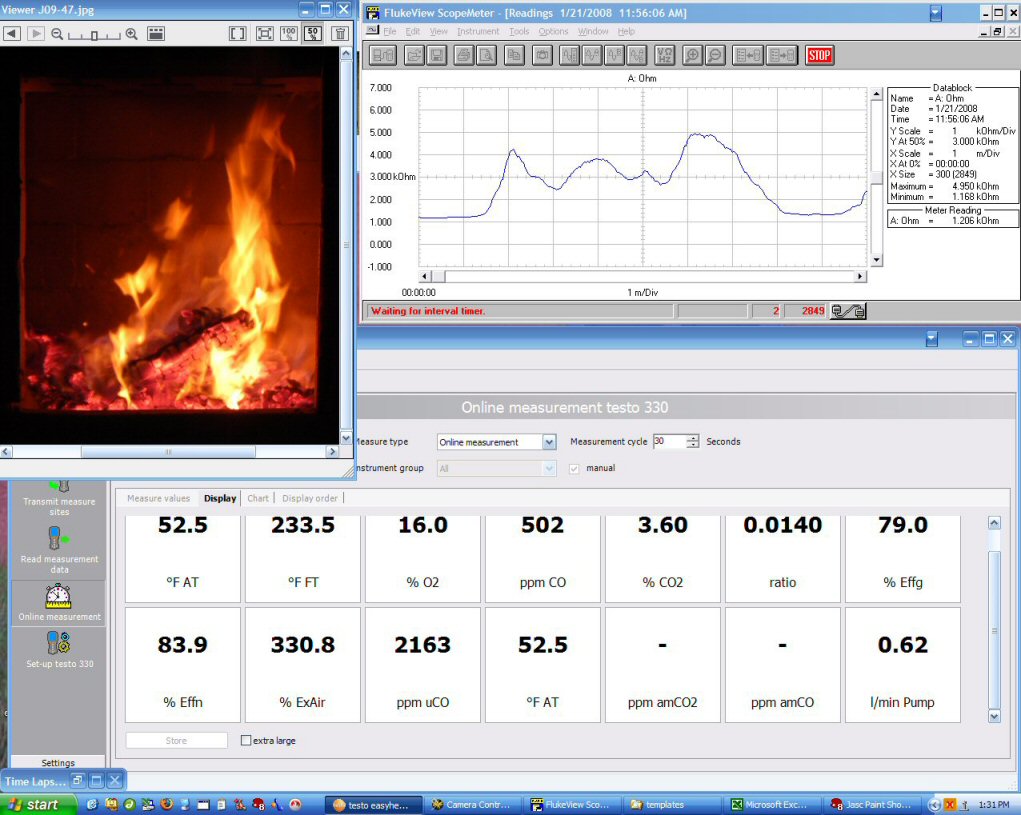

Computer Monitor - Screen Capture

Graph at top right is the opacity measurement.

Photo window shows the most recent photo in the time lapse series.

Bottom window is the data display from the Testo flue gas analyzer.

Condar calibration done in New Zealand against dilution tunnel method AS/NZS 4012/3

Comments

and Progress Reports:

Test Results

February 4/08: Preliminary data analysis

January 28/08: Correlation between Condar PM number and Opacity Curve

January 17/08: Graphical data summary

January 15/08: With the new air system, and the new Side Burn method, Condar particulate numbers with seasoned hardwood are consistently under 1 gram /kg so far, provided the heater is warm to start (fired 24 hours previously). Update: Feb 4/08: this conclusion is still valid after 18 runs.

Links:

Condar (Oregon Method 41 (OM41)) Technical Description

Condar Manual

2005 New Zealand pellet stove field study done with the Condar

The Story Behind the Condar

Lopez archive of wood combustion technical information

|