Calibration of 4 Condar portable dilution tunnels

Cold Climate Housing Research Center (CCHRC)

Fairbanks, Alaska, October 21-31, 2007

Photo credits: Dave Misiuk, Norbert Senf Test Results History of Method 5 and the Condar by Dr. Barnett, its inventor

Operating Manual for the CondarFebruary 15, 2014: OMNI Correlation testing of the Condar with EPA method 5G-3

2005 New Zealand pellet stove field study done with the Condar

Graph of results.

Tests a02 - a07 were with 2 Condars, low in the stack. Mixing was poor at this location.

Tests a08 - a15 were with 4 Condars, higher in the stack.

February 15, 2014: OMNI Correlation testing of the Condar with EPA method 5G-3

CCHRC, viewed from the University of Alaska. It is separate from the

University, and mainly supported by industry. The new test lab is just

behind the large

bay door on the right.

Dan Givens on the left. He is a local Fairbanks heater mason, and

donated the two heaters for testing, as well as a lot of labor helping

us out.

Dave Misiuk is a Professional Engineer and CCHRC's new wood combustion specialist, in charge of biomass research.

Norbert Senf (Lopez Labs) on the right.

4 Condar portable dilution tunnels, used for measuring emissions of

particulate matter (PM). The goal is to calibrate them against EPA

method 5G,

and the new ASTM dilution tunnel method, which uses a larger tunnel than the EPA one

.

The far right one is a rare original, owned by Jerry Frisch (Lopez Labs).

The other three are new ones that Jerry had custom built. He has donated one to MHA, and CCHRC will keep one of the others.

The

goal of the research described here was to run the 4 Condars

simultaneously on a masonry heater, and cross-calibrate them against

each other. OMNI-TEST labs, an EPA-accredited facility in Portland,

Oregon, has a Condar that they recently referenced against EPA

Method 5. Myren Consulting is an EPA-accredited lab in Colville,

Washington, and has also recently run a Condar against the new ASTM

dilution tunnel with a masonry heater. Further calibration work with

the Condar was done in conjunction with field testing of pellet stoves

in New Zealand in 2007(see bottom of this page).

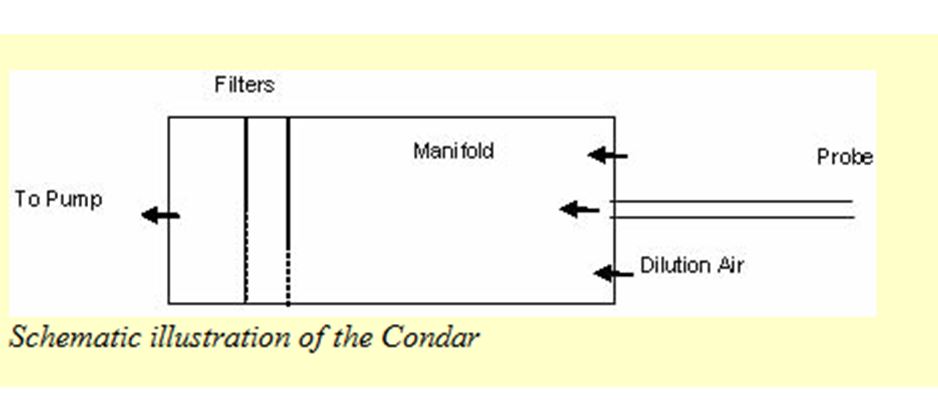

Schematic illustration of the Condar

Fairbanks

North Star Borough, Alaska, is about the size of New Jersey, and has a

population of about 90,000. They have an air quality

problem from wood combustion, due to surrounding mountains. CCHRC has a grant from the Borough and has been charged with

investigating and making recommendations on formulating an

implementation plan to get into compliance with federal air quality

standards for

PM-2.5

PM-2.5 is particulates smaller than 2.5 microns. Blue woodsmoke (tar particles) are all smaller than 2.5 microns.

It would be fair to say that most of the filter catch in these tests at

CCHRC was soot. Tar is produced by smoldering combustion. Soot is

produced

from a flame. If combustion gets too fast from small, dry wood, it

can't get enough mixed in air, resulting in fuel-rich conditions, which

results in soot formation.

In preparation for our testing, an exhaust hood was installed inside

the lab, since the test method requires that the chimney exhaust

inside the test room.

White birch cordwood. It will get a plastic wrap to stabilize it around 20% moisture.

Dan Givens donated this prefab heater, which is made in Holland and assembles in 2 hours without mortar.

Curing with an electric heater inside the firebox. Visible at the back

is an assembled Swedish Kakelugn (Royal Crown) core that Dan

bought from Jerry Frisch at the 2007 MHA auction. It had a facing by the time I arrived.

The Swedish was originally field tested by OMNI about 10 years ago, and

recently retested by them to the new proposed ASTM standard.

Dan and Dave assemble the chimney.

Day 2: ready for a shakeout run. Jerry's original Condar is attached

just above the exit at the top of the heater. There is a control board

on the wall

at the right.

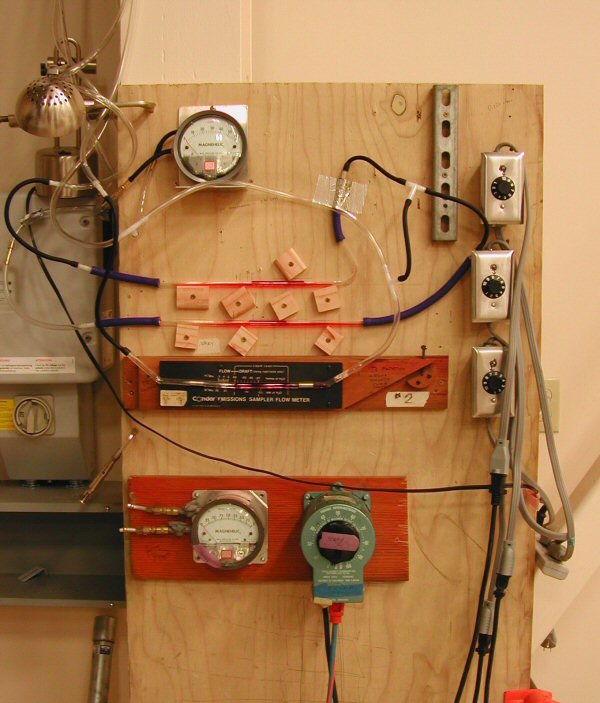

Assembling the control board. The most valuable item is the inclined

tube micromanometer, with its original calibration certificate

matched to the original Condar. We will use this to calibrate the

Magnehelic gauge. At the bottom right is a Variac, which is

a variable voltage transformer used to control the suction motor on the

Condar. Cords are hanging from disassembled speed controls for the new

Condars.

The Condar has a calibrated 3/8" nozzle that draws a sample from the

stack. A pressure tap on the nozzle (attached to the plastic tube,

which goes to the control panel), is used to keep the vacuum in the

chamber, and hence the flow rate, constant. The vacuum sucks the

sample onto a pair of filters. As the filters load up, the motor speed needs to be increased to maintain a constant vacuum.

Shakeout run. Various friends dropped by to check it out. Dave is

talking to Dave #2, who is the facilities manager at CCHRC, and was a

great

help to us. CCHRC's mandate is to disseminate "best practices"

information to the building industry, so the lab welcomes visitors.

The lab lights are turned off so that we can take a time lapse photo series of the burn. Dave adjusts a motor to

maintain a constant pressure

(about minus 12 pascals on the Magnehelic)

Real time readings from the Testo 330-2 combustion gas analyzer.

Weighing filters on a digital laboratory analytical balance. Filters are weighed to 0.1 milligram (.0001 g).

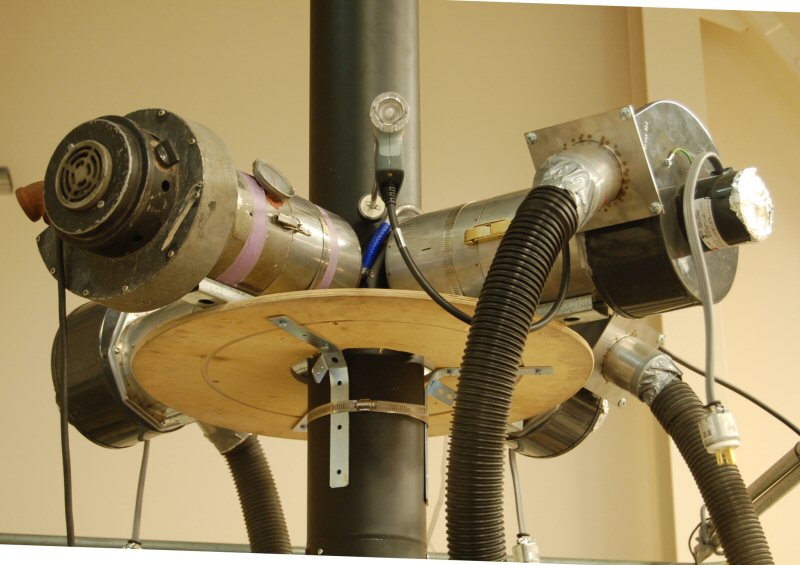

We were not getting good correlation with the first two Condars. After

much discussion (and reading

Skip Barnett's original manual), we decided to mount all 4 Condars further downstream. This is a mockup of the mounting system.

Dave Misiuk fabricated the mounts.

Dave is also a trained machinist and certified pressure welder. Here he welds up an airframe for the

Swedish heater door.

We

had to improvise a lot, as the budget and time were limited. The motors

on the new Condars didn't have enough power, and we were

able to

solve the problem with 3 shopvacs and some duct tape. It turns out that

you can run a Shopvac off a speed controller.

Fitting the Condars to their new location. This proved to be the fix, much to our relief.

From

9 valid runs at the second location, we got filter catch correlations of

between plus or minus 2% to plus or minus 10%. We considered this as excellent, since particulates are

notoriously difficult to measure reliably and repeatably.

Rigging the shopvacs and the instrumentation.

Final sampling setup. Control panel is on the wall to the right.

Testo probe is the small one in between the two front Condars. It has a

quick change filter that needs to be dried out between runs.

Dan Givens helps out with filter changes. Dan spent as much time

helping at the lab as he could, even though he had a project on the go

about 2 hours away. We started most days around 9:00 am and often finished after midnight.

Building up the control panel.

Magnehelic is mounted at upper left.

We improvised 2 extra inclined tube micromanometers with parts we sourced at a wine store. (They

worked quite well). The red fluid is factory original Condar manometer fluid, freshly changed.

Everything was calibrated to the original Condar manometer.

Speed controls for the 3 shop vac vacuum sources at the right.

In order to maximize repeatability, we constructed identical fuel cribs.

Douglas fir 2x4's from a building supply were ripped in half. Moisture content was around 9%.

This gave us lots of soot (black smoke, as opposed to blue or white),

but low PM numbers -- soot without tar doesn't weigh much.

Fairbanks is very dry, and this is a typical moisture content for seasoned firewood up here.

View of the overall testing setup

Dan Givens installs the newly made airframe door assembly in the Swedish heater.

We got it ready just in time for "show and tell" for visiting dignitaries from the Circumpolar Housing Conference

The Circumpolar Housing Conference, organized by CCHRC, happened for 2 days during our project. Lots of super interesting stuff.

As a northern country, Canada has a lot in common with Alaska and other circumpolar states.

One of CCHRC's mandates is to evaluate and develop technologies suitable for Alaska.

Alaska has adapted a lot of leading edge housing technology from Canada.

Several groups of visiting dignitaries came by for a tour of the lab.

The lady at the left is a planning official from Mongolia. She

recognized the heaters as

similar to traditional Mongolian sytems with an open firebox. Facing

the camera in the huddle at the right is Oliver Drerup, senior housing

consultant

at CMHC.

Oliver was instrumental in the founding of CCHRC and is on the Board.

He was also very involved in starting Canada's R-2000 housing program.

He gave a very well received closing keynote address. Oliver is an old friend - we put a masonry heater into an R-2000 house his company

built

in Ottawa in 1985, a first at the time. The heater appears on the back cover of David Lyle's book.

|