| |

Alan Scott - Ovencrafters

Bakeoven Seminar with Alan Scott

Masonry Heater Association Annual Meeting,

Las Vegas, March 1995

Alan Scott is an Australian-born craftsman

whose first trade was as a blacksmith. He is now a baker and a well-known

designer and builder of wood fired brick bakeovens, both domestic and

commercial. He makes his home in a rural setting north of San Francisco,

where he practices the various aspects of his craft. We had the opportunity

to build one of Alan’s ovens four years ago for a small commercial bakery outside of Ottawa. I

was impressed with some of Alan’s design innovations that resulted

in a low cost, easy to build oven. After three years of commercial use,

the owners report that they are very happy with the oven’s performance

and in fact are planning to expand and build a larger

oven. Fuel cost per loaf of bread is two cents. Alan Scott is an Australian-born craftsman

whose first trade was as a blacksmith. He is now a baker and a well-known

designer and builder of wood fired brick bakeovens, both domestic and

commercial. He makes his home in a rural setting north of San Francisco,

where he practices the various aspects of his craft. We had the opportunity

to build one of Alan’s ovens four years ago for a small commercial bakery outside of Ottawa. I

was impressed with some of Alan’s design innovations that resulted

in a low cost, easy to build oven. After three years of commercial use,

the owners report that they are very happy with the oven’s performance

and in fact are planning to expand and build a larger

oven. Fuel cost per loaf of bread is two cents.

Features of the retained heat design. Alan started his presentation

by describing some of the features of his retained heat design:

- The largest size oven has 6 foot by 8 foot hearth area.

- The vaulted baking chamber ceiling consists of 4.5 inches of firebrick

capped by 2 inches of reinforced concrete (thus cleverly eliminating

the need for traditional structural steel to take up the vault side

thrust.)

- The ratio of door height to dome height is 63%.

- The oven is filled with wood, and a fairly slow fire results in a

very evenly heated oven.

- Smoke exhausts at the top of the door where it goes into a collection

hood.

- The dome is kept as low as possible, which provides the maximum amount

of steam.

- For breads, a 15" high dome with a 10" door is close to

ideal, while an 18" dome with a 12" door is more versatile

for restaurants.

Techniques for larger ovens. For larger ovens, more support for

the arch needs to be provided during construction. This can be done by

pouring the concrete supports for the sidewalls first. For restaurants,

calcium aluminate concrete is used. The thickness of the arch is increased

if more batches per firing are needed. A 6" arch will give 8 batches,

while the standard arch gives 4 batches - more for lighter bread. Heavy

breads require a hotter oven. This requires a more tricky firing technique,

and this is one drawback for this oven style. Hearths should be smooth,

with bricks laid up on edge, dry, onto a sand bed. Soapstone is too conductive

and results in too hot a hearth. Castable refractory hearths have peeling

problems. Allan’s philosophy, and advice to oven builders, is to

keep it simple. This is exemplified in the traditional Québec oven which,

however, is not as efficient.

Shown below is an oven built by Allan Scott at the Cafe Beaujolais in

Mendocino CA. The oven has been in service for about 8 years. Click on

image for an enlarged view.

Bread is the starting point. The starting point for oven building

should be the bread. Alan advocates a switch to a more appropriately scaled

economy and lifestyle, and his oven designs and his bread reflect this.

Pizza ovens use a continuous fire in the oven during the baking. This

automatically results in the required high air temperature (700F). This

same style of oven is used for middle eastern food such as pita, matzoh,

etc. Bagels are also done this way. Using this type of oven is labor intensive

and requires a lot of skill. Storage capacity is not really required in

this type of oven, and castable refractory is an appropriate material.

A small prefabricated Italian oven starts at

about $6000, but a homebuilt version can be built for around $150.

The breadbaking revival. The Poîlane bakery in Paris is widely

considered to be at the pinnacle of the bread baking art. They use a wood

fired brick oven. The oven is hot, resulting in a seared, dark crust.

The bakery has recently expanded in an interesting way. Rather than build

larger ovens, they have replicated their existing oven design 24 times,

with the ovens arranged in a large circle. Each baker has his own village-size

oven - about 12 - 14 feet square. An article on Poîlane can be found in

the Jan/Feb

1995 issue of Smithsonian magazine. Another article about Poîlane

included a photograph of the owner in the local forest, inspecting his

firewood supply. Alan feels that this is a right use of wood, and stimulates

the forests. (French forestry practices have been enlightened for a long

time. France has about 1/7 th the forest area of Canada, but produces

a higher dollar volume of forest products. 200 year crop rotations are

not unheard of.) One thing that is apparent on the West Coast is that

a bread revival is under way. Two good recent books on the subject are

The Village Baker by Joe Ortiz

and Bread Alone by Daniel Leader and Judith Blahnik.

A brand new book, and perhaps the best one so far, is: Breads from

the La Brea Bakery by Nancy Silverton.

Bakery visits. Alan handed out a list of ovens that he had built,

and we had the opportunity to visit two of them on our drive from Las

Vegas to Vancouver.

We also visited several other notable bakeries. Jerry Haupt arranged

a visit during a burn for Patrick Manley and myself to the Black

Diamond Bakery in Black Diamond, WA. They have a woodfired bakeoven

with a 10’ x 12’ hearth that has been in continuous use since

1902. Wood consumption on this oven is quite high at 0.5 cords per day.

My guess is that this could be cut by 75% using modern materials and techniques.

We also visited Acme in Berkley and Gail’s

in Capitola CA.

Ideal firing technique. Alan finished his presentation with a

discussion of firing techniques:

- Any type of wood is suitable, and it is a nice niche for limb wood,

around 2" in diameter.

- Long lengths can be used, around 4 to 6 feet.

- Diameter should be larger for softwood. Larger diameter wood results

in more of the heat going into the hearth, and vice versa.

- A kindling fire is built in the mouth of the oven, and the fire is

allowed to burn slowly to the back.

- The fire can be encouraged by raking the coals.

- If you reload, then you cut off the air supply to the first load.

You have to wait for the first load to burn before adding wood.

- The front of the oven will be a little cool because of the air supply.

Coals are raked to the front as the last thing.

- A damp mop is used to remove the ash from the hearth.

- Allan uses a wooden door plug cooled with a damp terrycloth. The bread

is done when the towel starts to burn.

- The widest door for a 48" oven is 24". Usually the door

is 19", to fit a standard 18" pan. There can be problems with

doors that are too wide, ie., if automatic loading equipment is used.

- Firing times for a 4 x 6 oven are approximately as follows: from a

cold start - 3.5 to 4 hours; a warm oven - 2 to 2.5 hours; third and

subsequent days - 1.5 to 2 hrs.

- Preheat the oven the night before - it doesn’t take much more

wood.

Additional tips:

- A good rhythm is to bake 2 days per week. At the Cafe Beaujolais in

Mendocino, the oven is usually 425F in the morning. They prestack and

bake the wood.

- Good sourdough bread will last for several weeks. The fermentation

that the yeast undergoes in sourdough bread is important - it adds nutrition,

and makes the bread more digestible. The challenge is not to make the

bread too sour.

- For rye bread, a cool oven is used, around 300 degrees. Steam the

bread while baking, and then leave it for 24 hours.

Afternoon Technical Session: Dale Hisler

After Alan’s presentation, longtime heater mason and baker Dale

Hisler shared some additional tips with us.

- Dale recommends the installation of an ashdrop at the back of the

oven.

- One way to gauge oven temperature is to sprinkle some flour onto the

floor of the oven.

- Dampers are an important element for regulating oven temperatures.

- For sourdough, a starter can often be made from existing sourdough

bread.

- Steam can be added by installing copper tubes to trickle water onto

the oven floor.

- Large ovens tend to have complex damper systems, and a personality.

Alan Scott, 72, Artisan of the Brick Oven, Dies Alan Scott, 72, Artisan of the Brick Oven, Dies

New York Times, Feb 6/09

|

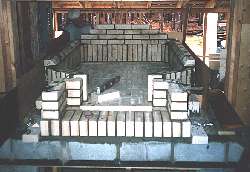

Below:

Oven at Little Stream Bakery under construction by the author

(Masonry Stove Builders). Click on images for enlarged view.

View of side hearth and side walls before construction

of vaulted ceiling. This is a small oven, with a 4 foot by 6 foot hearth.

View of finished vaulted ceiling. This oven has been in

commercial use for 5 years and is currently producing

1800 loaves of sourdough bread per week. Little Stream

has expanded to larger premises and built a larger oven.

Adapted from a report by Norbert Senf in MHA News

The following exchange recently took place on the Brick Oven Listserver

Date: Decemer 8, 1998

To: brick-oven@onelist.com

From: Alan Scott <ovencrft@nbn.com>

Mailing-List: list brick-oven@onelist.com; contact brick-oven-owner@onelist.

Subject: [Brick-Oven] Re: Whole Grain vs.

Dear Randy:

Glad to hear of another potential whole grain baker as it is what got me

into designing the brick ovens in the first place and still my preference,

in fact my staple bread. To this end I not only research and build the

ovens, I also import appropriate equipment, mixers and grain mills from

Europe, if there are none available locally.

Nutritionally speaking, I think one needs

to use only the natural starters and to thoroughly ferment the dough before

it is baked. This is a process that insures that no nutrients are out of

balance in the finished loaf and all are also available. The trick is to

catch the fermented dough before it is too far gone to either create a

too sour bread and lose some nutrients in the process, or have the bread

not rise enough to make the most of the gluten. Of course in rye breads

there is almost no gluten so the bread is thoroughly fermented but no one

expects a fluffy loaf.

Just to make it difficult, the nutrition

oriented baker will want to use only the freshest whole grain flour and

as the leading baker in the country at the moment (in my opinion that is,

Dave Miller of the Millers Bakery, Chico CA), says, he wants his mill to

drop the flour directly into the mixing bowl, not only fresh but still

wriggling with life forces! This cuts against the grain of everything that

industry has been researching and doing for the past century, but I have

never had better bread.

As for the milling, there is a lot to be

said for the stone milling and it has a reputation as the best way to go,

based on two things: one is that a slow turning stone mill will never heat

the flour over the critical 116 degrees when the nutrients begin to be

destroyed, and secondly that the old large millstones not only ground and

pulverised the whole wheat into a fine flour, they also rubbed the precious

oils well into the flour before it left the mill. This last process helped

to preserve the value of the oils (nutritional value that is) a little

longer than if they were not rubbed into the flour.

The end result of this to a conscientious

nutritionally concerned baker would be a flour that could be aged a little

(would give a competitively lofty loaf) yet still have most of its nutrients

intact. Industry today could care less about nutrition so milling is for

other reasons and one can never find a good flour from any mill large or

small at the moment.

The answer to me is to grind your own,

and to this end there are a couple of natural stone mill on the market,

but you will have to put up with the constant sharpening of the stones

to give a marginally fine flour, and no oil rubbing effect, or to go with

a composite natural stone mill that gives a finer flour without high temperatures

and little maintenance. Guess what? I happen to import just such mills

and these range in size from table top (100 lbs. per hour) to 48"

stones (1000lbs per hour). There are also sifters to go with them, which

I do not recommend.

You have the right idea about keeping the

starter fresh. I have many bakeries that are baking in the brick ovens

and do exclusively whole grain breads if you need to network with some.

I can send a list. Cheers, ALAN

------------------------------------------------------------------------

Click here to order.

Click here to order.

by Daniel Wing and Alan

Scott

Definitive work on authentic hearth breads,

including instructions for building a backyard bake oven.

Your webmaster rates it a 10

"Wing and Scott do more than get the details right:

they get the right details. It is difficult for me to imagine any baker, amateur

or professional, coming away from this book without having learned something

significant, even profound, about the art of bread baking."

-Thom Leonard, author of The Bread Book

Retained Heat Oven Data - now available in

the book.

See also:

Backyard Bakeoven Workshop with Norbert Senf

step-by-step construction photos of a 32" X 36" oven.

This page last updated on

July 7, 2009

Back to Masonry Stove Builders home page:

Click here to order.

Click here to order.