| Heat-Kit | Gallery | Library | Brick Oven Page | |||||

| Current Projects | Contact | Bookstore | Links |

May 3, 1998

Oven footprint is laid out on floor. Floor will be used to form a 3.5"

reinforced

concrete base pad for oven.

The black 220v. power supply cable for the oven can be seen hanging from the

ceiling.

Slab is formed. Form is lined with 6 mil poly.

A 4' x 8' sheet of 6" x 6" reinforcing mesh is cut up and placed in

the form

May 15

Slab is lifted onto a welded steel frame. A 2.5" thick slab would have

been a

lot easier to lift.

May 19, 1998

A 24" x 36" rectangle is marked out on the slab.

4" of Dow Corning Foamglas foamed glass insulation is laid

in a mortar bed. This oven is for intermittent use. For an oven for

daily use, where more mass is desirable, the concrete slab can be used for mass

and the foam glass attached to the underside and sides of the slab with

GE silicone.

A hearth of 6" x 9" x 3" firebrick is set dry onto the foamed

glass.

The foamed glass has a compressive strength of 100 psi.

May 20, 1998

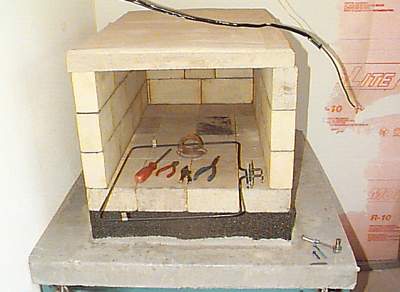

A form is built to cast a 2.5" thick slab of castable refractory for

the

oven ceiling. Two dowels are located as shown as knock-out plugs for

where the electric wires will pass through. To the left is a metal divider

strip that separates the slab into two pieces, for easier handling later.

The material for the ceiling will be "Kast-Set" from A.P. Green Refractories.

Almost any other general purpose castable refractory would be adequate in

this application.

The side and back wall are built from standard 4.5" x 9" x 2.25"

firebricks.

The bricks are set in a thin bed of clay.

The bake chamber without ceiling

May 23

Precast ceiling is installed. 3000 W. oven element (available at any hardware

store)

is ready for installation.

Oven element mounting detail. Blue screw is a Tapcon self-threading

concrete screw.

May 24

Detail of installed oven element

Right side is framed with metal studs. A wooden ledger is glued to the left

wall.

Oven insulation is started. "Roxul" brand rockwool batts are used.

These are

widely available in Canada as an alternative to fiberglass insulation batts.

They

are fireproof, more rigid, and easier to work with.

Front view.

May 25

Test bake. Sourdough.

A piece of Foamglas is used as a temporary oven door.

May 29

The door plug has had a 1" facing of refractory insulating board

(Insblok 19 from A.P. Green Refractories) and a sheet metal jacket

added. Thermal shocking was cracking the bare Foamglas plug.

A data acquisition system has been installed to record oven temperatures.

The data will determine if more mass should be added to the oven before finishing.

The tradeoff will be between additional warmup time (or a second oven element)

and the number of bakes between recharging the mass with heat.

An inexpensive 5 channel thermocouple interface from Accqu-Data plugs into an

old 386SX laptop. It comes with nice software, and logs data to an Excel spreadsheet

as well as providing an on-screen temperature readouts and a graph.

July 3 - Update

2.5" thickness has been added to floor, and oven is in use while data

is gathered.

September 17 - Update

Other projects have intervened. The oven is in regular use. The plaster

finish inside the bakery is nearing completion, and the oven will soon receive

added thickness on the ceiling, a vertical sliding door, and completed insulation

and finish.

September 21

Vertical sliding loading door. Welded 3" angle iron door slides

inside standard sliding door track.

March 13, 1999

Other projects and winter has intervened, so not much more progress:

Right side is closed in with cement board screwed to the metal studs.

The sliding door has been insulated with 2" foamglass and a sheet metal

cover.

Door mechanism comprises a rope, 2 pulleys, and a partially filled bucket of

sand.

Sourdough bread.

May 1:

Oven is fully closed in. Door pulley systems has been revised. There is a HUGE

difference in heat

retention due to cutting off convective air flow losses in the insulation by

closing in the oven. See

temperature graph below:

Oven temperature record over 5 full days. When oven is refired and then turned off, note initial steep temperature drop as heat soaks from surface to inside of bricks. Once bricks are stabilized, drop off is very slow, for example from 490 to 316 in 24.75 hours.

The oven has been in regular use for making levain, an authentic French style

country loaf using sourdough only, no yeast.

| Heat-Kit | Gallery | Library | Brick Oven Page | |||||

| Current Projects | Contact | Bookstore | Links |

This page last updated on May 26, 2007