The manner in which a masonry heater is operated can have an enormous effect upon the heaters efficiency and longevity.

Though the technical knowledge and skill of the stove builder are essential, the real responsibility for combustion, and overall, efficiency rests with the operator.

The Moisture content of the wood burnt is absolutely crucial. Wood must be seasoned, ideally for two years, and kept under cover until it contains less than 17% moisture. (Moisture content is by weight, moisture accounting for 35 to 60 percent of the weight of freshly cut wood.)

This cannot be stressed strongly enough. The difference between wet and dry wood is the difference between being cold or warm.

|

Well Seasoned Beech |

All tree species can be used as fuel for masonry heaters. Both hard and soft wood have roughly the same calorific value weight for weight, though hard woods are denser.

In Southern Quebec mostly hard wood is burnt, and Poplar is considered a poor wood. In Northern Quebec where the only hard woods are Poplar and Birch, it is considered normal to burn Poplar. Areas of Ukraine have traditionally burned faggots of grass on their masonry heaters.

Density of North East American Firewood's. From Hard to Soft.Regular cord wood is of ideal size. Smaller branch wood or scrap can be mixed with good hard wood. As long as it is all dry. A full fire of branch wood and scrap can be lit, it would burn faster and give less of a thermal charge than a fire of hardwood logs. Two medium sized fires (morning and evening) of branch wood, would give roughly the same thermal charge as one large fire of cord wood.

|

The fire box can be filled with wood. Here a medium sized fire is stacked for a top down burn, fed by over air. |

There are two ways of stacking the wood load, each a contradiction of the other.

Traditionally a 'bottom up' fire is layed with paper on the bottom, kindling and finally large wood. The flame burns vigorously up through the wood load as the fire becomes established.

The 'top down' method places the logs on the bottom, smaller pieces upon them and kindling on top of this. The fire is lit at the top and slowly burns down through the wood load. (See: High Performance Masonry Heating)

With the top down burn, as the fire begins to become established the flames do not pass through the wood load, causing gasses (that will not burn due to the low temperature) to be liberated and lost, as is the case with the initial stages of the bottom up burn. By the time the fire falls onto the logs and they begin to outgas the gases have to pass up through a vigorous, well established, fire where they burn.

As the top down burn takes time to slowly become established, there is much less thermal shock each time the heater is fired. The top down burn will function best if the heater is set up to receive over air.

|

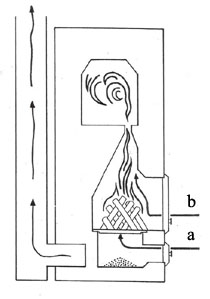

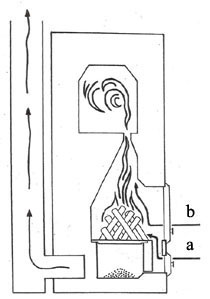

Under air |  |

Over air |

a - Primary Air, b - Secondary Air |

|||

Once lit the fire should burn until out. The fire is never recharged, and the firebox door only opened if necessary. If the heater is fired continuously the mass will, after saturation point, start to absorb heat faster than it can transfer and expel heat into the living area. At this point the heater could be irreparably damaged by thermal stress.

The combustion should be as rapid as possible, about two hours for an average fire. The damper needs to be closed as soon as the last embers have burnt away. This closes the smoke path and stops the thermal charge thermo-syphoning off the mass due to the chimneys draw. During the later stages of combustion the damper can be closed gradually in relation to the quantity of embers still burning. The damper should have a 5% safety cut out that allows a constant slight thermo-syphon through the system. The damper can then be closed knowing that if there is a flare up of one of the embers the gasses it produces will be drawn through the smoke path and not spill out into the home.

A masonry heater burns wood in a fast and vigorous manner. At the start of the fire the chimney damper and primary air intake draft slide should be fully open.

Once the fire has become established and the fire box walls saturated with heat, the temperature of the fire increases to 600 degrees Celsius allowing secondary combustion.

|

Looking up in to the firebox one hour and a half after the start of a top down burn. Top foreground can be seen the refractory brick heat shields of the firebox lintle, and the corbelled firebox ceiling. |

At this point all the dark carbon deposits should be burnt and the inner surfaces of the fire box become white. If the fire box is black once the fire has been burning for some time then something is being done wrong.

Once the fire has become well established the chimney damper can be partially closed if necessary to restrict the draw through the smoke path. The flame should be as light and yellow as possible, if the flame is dark red and purple, then the fire lacks air and the damper should be opened.

|

|

|

||

|

||

|

|

Pyromasse heaters are fed by over air. This is taken in through the draught slide below the fire box door, up a channel between the core and facing, and deflected onto the wood load at an eighty degree angle.

Some of the early Pyromasse heaters were fed by under air which came up through the grate and passed through the wood load.

There seems to be a consensus now that over air is preferable. Under air produces too vigorous a fire and can contribute to premature breakdown of the interior surfaces of the fire box. Over air feeds, but doesn't force feed the fire, providing just enough air at the rate desired to give maximum efficiency. An Upo ash box door, that has a draught slide is located directly beneath the fire box door and used to admit over air from the living area.

The Upo fire box doors used by Pyromasse have one or two draught slides in the door frame. These allow secondary air into the firebox which by passes the primary combustion, rising, unburned, to nourish the secondary combustion. These draught slides can be closed at the same time as the damper, when the fire is out.

|

Primary air deflectors inside the firebox. |

A heater can be fired once, twice, or even three times per day depending upon the weather. Though three fires per day on a regular basis is considered excessive and not recommended. The rule is to allow at least 5 hours between fires. Most heater operators find that one fire per day is often enough. Two medium sized fires per day could be had in place of one large fire. In mild weather one fire every two days is often enough.

Regardless of the number of fires, with a Pyromasse heater, no more than 100 lbs of hard wood should be burned within a a 24 hour period i.e. per day.

Once lit the fire should not be re loaded or have wood added towards the end.

The chimney trap should be kept closed between fires.

Once warm the heater should, ideally, be kept warm all season.

When cold a heater should be warmed with a small priming fire before lighting a large fire. This limits the inevitable thermal shock that occurs each time the heater is fired.

Never light a large fire when the heater is cold.

Never light fires out of season, or for their ambiance.

The heater operator needs to maintain a relatively close relationship with the weather as the heater, once warm,, remains warm for hours or days, especially in mild weather.

Each time a heater goes through its firing cycle

it suffers thermal shock. Though if the heater is in constant use, this shock is

minimal. Ideally a heater should be lit once at the start of the season and kept

warm until spring.

Fires for pleasure in summer should be avoided.

If used with respect a heater should last a life time.

If the damper is closed too soon then smoke may spill into the house. It is strongly advised that the house be fitted with a smoke and carbon monoxide detector.

During combustion the fire box doors should never be left open. This will lower fire box temperatures, stop secondary combustion, and cause the side channels and manifolds to become coated with creosote.

Nothing combustible should be placed upon the heater e.g. clothes to dry, boots, socks. They probably will not burn, but with fire we cannot take chances.

In Northern Europe a rail was often suspended from the ceiling, parallel to one or more sides of the heater. This could then be used to suspend wet clothes close to the heater. See: Valperkins

If the heater is built upon an elevated masonry foundation and the void inside the foundation is used as an ash dump, ash removal will be necessary about every eight years, though it can be done annually.

The heaters manifolds have an access door which allows them to be inspected and cleaned.

There is a potential for fly ash to accumulate in the manifolds, though I have always found that the draw prevents accumulation of fly ash in the manifolds.

The chimney does not need to be swept as little or no creosote will be deposited on its inner surfaces. It is recommended though that it is swept once every two years to make sure there are no blockages, and to inspect the masonry of the chimney top.