Clearance to Combustibles Testing

MHA Annual Meeting, Wildacres, NC

April 19 - 20, 2000

Introduction

Summary of Results

Discussion

Conclusion

Data Sets

Photos

Introduction:Efforts are under way to update the clearances to combustibles requirements for the ASTM Guide to Solid Fueled Masonry Heaters. In order to obtain baseline data to serve as a basis for discussion, a test heater was built with 3 firebox wall sections: (left wall): 8" soapstone (all dimensions nominal) 4 fuel loads of 50 lbs of hardwood at 14% moisture were burned back to back. Surface temperatures were recorded at 3 locations on each wall. 2 separate sets of readings were taken by 2 crews with 2 different infrared thermometers. Summary of Results:

Discussion:UL-127 Temperature limits on combustible surfaces are: 90F over ambient room temperature for unexposed (ie., in contact and

covered) surfaces and Testing done at Lopez in January 2000, indicates that in order to obtain 117F above ambient with a 4" ventilated air space, a heater surface temperature of approximately 350F is required. |

Below are the results with a horizontal line indicating the

350F surface temperature limit.

The firebox wall built in accordance with current fireplace building code, ie., with a

firebrick liner

and an 8" wall thickness, meets the UL surface temperature requirement at 4"

clearance to

combustibles when overfired by 400%.

Download the data in Excel 97 format. Check back regularly for updates

Ben Hurd, Albie Barden, and Jerry Frisch start building the heater

for clearances to combustibles testing.

Rod Zander and Albie Barden study Jerry's technique.

Ron Karson lays up the 8" soapstone left firebox wall.

Albie Barden works on the 8" brick right wall. The rear

wall is 4.5" firebrick.

The 8" soapstone test panel is visible. It is isolated from the

back wall by a strip of insulating board.

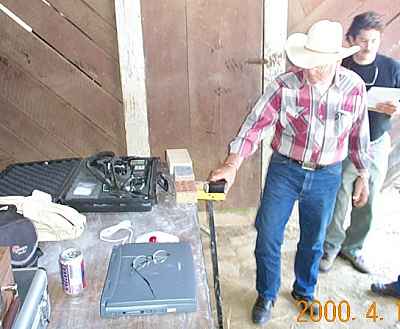

Lopez Labs field setup. Jerry reads the ambient surface temperature

of three different bricks. Combustion analyzer is in the black case at

rear. Laptop computer in front. Also present are a wood moisture meter,

digital camera, and thermo-anemometer.

Ron Karson records readings.

Ben Sotero takes a surface temperature reading.

The infrared thermometer is point-and-shoot, and

tales a reading instantly.

Pat Manley was on the fueling documentation team. Every piece was

weighed and measured for circumference with a cloth tape (this provides surface to volume

data).

Each fuel load was documented photographically.

First load stacked in the firebox.

Ready for a reload

Pat Manley reloads. The first test consisted of 4 back-to-back

burns of 50 lbs each (200 lbs total). Fuel moisture was 14%.

Weather during the first test was sunny and calm.

Marty Pearson checks the flueliner, which was running at

about 500 F on the surface.

Ron Karson and Rebecca Carnes perform a flue gas analysis as

Dan Fisher looks on.

This page last updated on June 1, 2008

This page created on May 9, 2000