MHA Research Heater

photos by Norbert Senf

Go to Testing Data

Oct 31/15: Heater build

Dec 20/15: Modification 01 (firebox)

Feb 15/16: Modifications 02

Jan 14/17: Instrumentation

Jan 19/18: Modifications 03 (chimney)

Jan 29/18: Modifications 04 (heat exchanger)

January 18/19 Modifications:

-- Chimney modification to conform to EPA

laboratory testing conditionsChimney modified to be substantially equivalent to NSPS (EPA) certification testing, which

requires the exit to be inside the laboratory at a height of 15' +/- 1'.

Height of Tee is at 17'.

T is 7" diameter, as is the chimney below. This is vented above by 6" diameter insulated chimney.

The T bleeds air into the chimney and brings the pressure at the junction to 0.

This sets the chimney draft equivalent to a 17' high inside exit chimney.

January 29/18 Modifications:

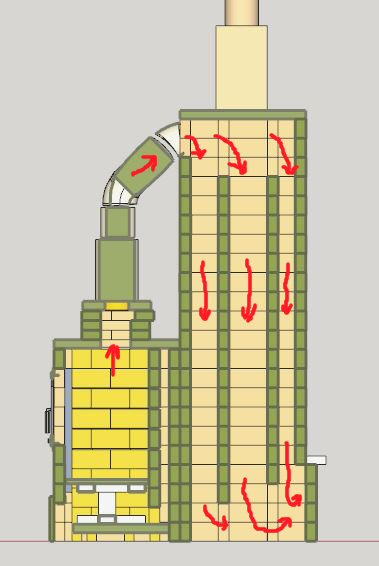

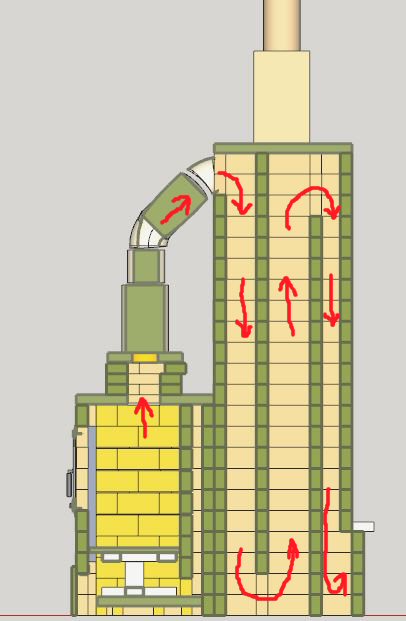

-- Reconfigure channels from parallel to serial

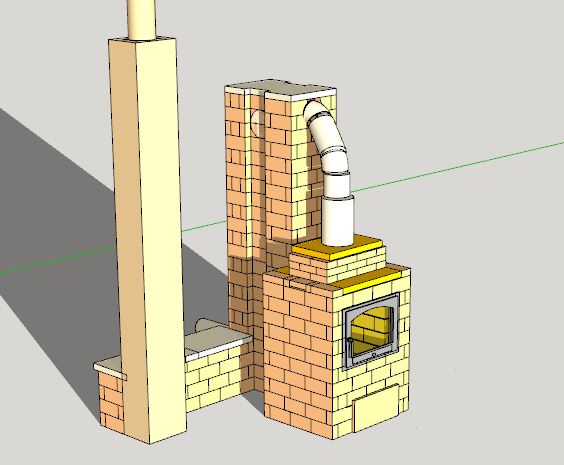

Heater firebox viewed from instrumentation room side.

Firebox is connected to heat exchanger via insulated chimney pipe.

Heat exchanger exits into heated bench.

Heated bench is connected to chimney.

Cross section through firebox, insulated connecting pipe,

and heat exchanger. Gases exit at bottom right into heated

bench .

Reconfigured heat exchanger.

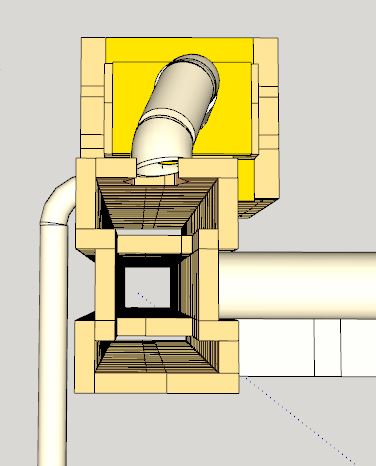

Original layout with the heat exchanger ceiling removed.

Around the edge is a ceramic fiber gasket.

A thermocoupld and pressure sensor tap are visible

View from above.

http://heatkit.com/research/MHA%20research%20heater%20mods03.htmhttp://heatkit.com/research/MHA%20research%20heater%20mods03.htmhttp://heatkit.com/research/MHA%20research%20heater%20mods03.htmhttp://heatkit.com/research/MHA%20research%20heater%20mods03.htm http://heatkit.com/research/MHA%20research%20heater%20mods03.htmhttp://heatkit.com/research/MHA%20research%20heater%20mods03.htmhttp://heatkit.com/research/MHA%20research%20heater%20mods03.htmhttp://heatkit.com/research/MHA%20research%20heater%20mods03.htm

Same view.

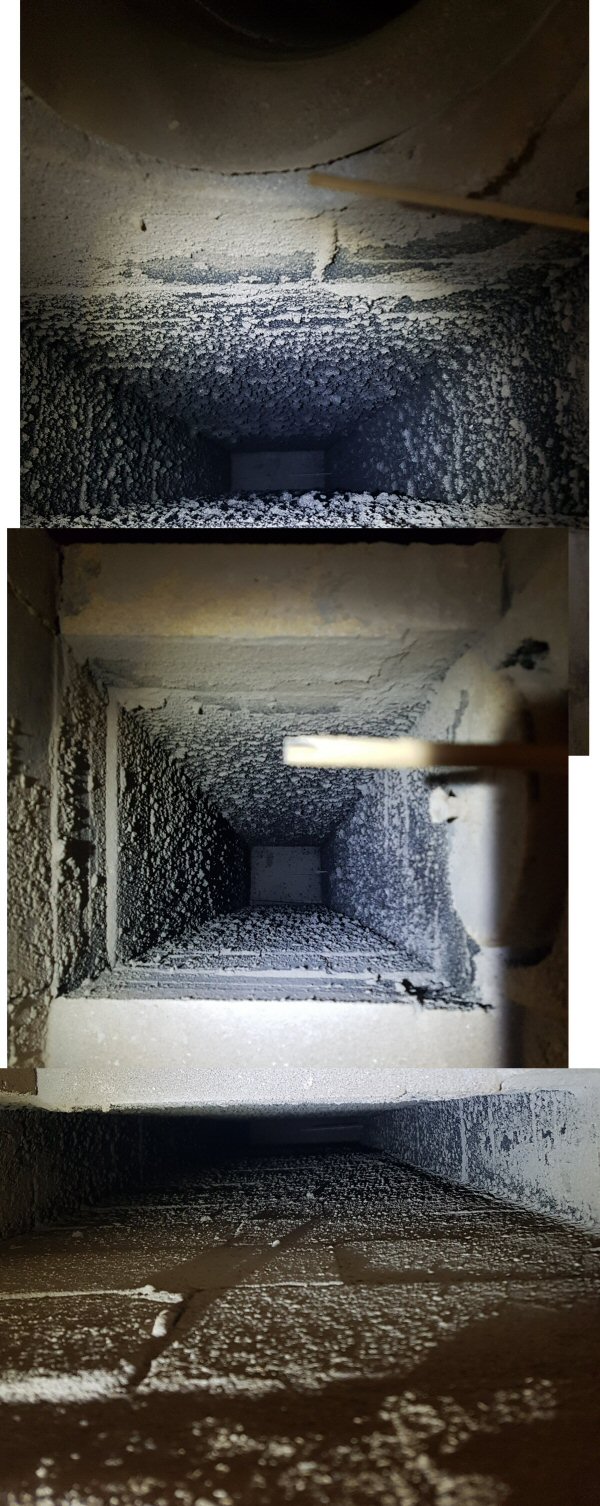

Composite photo of existing condition.

The chimney pipe inlet area was repaired.

Bricks added to reconfigure the gas flow.

Go to Testing Data

Check out other current

research at Lopez Labs

|