MHA Research Heater

photos by Norbert Senf

Go to Testing Data

See also:

October 31/15: MHA Research Heater construction

December 20/15: Firebox modification

February 15/16 Modifications:

-- Install pressure and temperature probes

-- Install scale under firebox floor

-- Raise firebox ceiling exit

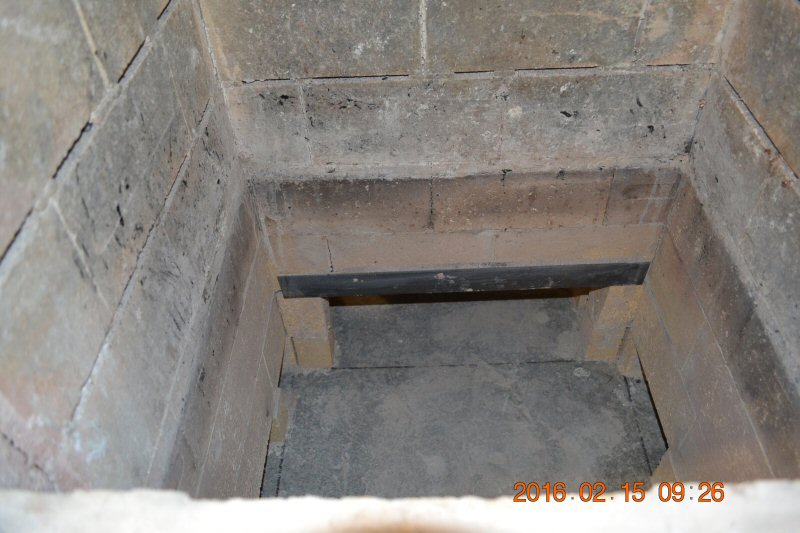

The 2 firebox floor slabs have been removed and are leaning against the heater.

A considerable amount of ash had slipped by the 1/8" gap around the edge of the floating firebox floor.

The

cutouts below the left and right firebox walls are to feed the

combustion air slots, visible in the horizontal firebrick joints in the

firebox.

The cutout to the rear is needed to accomodate the Adam GFK 165ah scale that will weigh the wood during the burn and give us the real time burn rate.

Removing the firebox door for better access.

Removing the chimney connection

Firebox ceiling with partial insulation still on.

The ceiling slabs get very hot, and there is some movement visible at the joints.

To increase the airtightness of the heater, we added a layer of glass mesh and clay plaster that wraps around the edges.

Note the 1" of insulation (yellow Roxul Drainclad) on the exterior sides, covered in cement board.

The firebox extension will sit on angle irons, that are supported only on the ends by 1/8" steel shims

The bulk of the angle iron will sit on 1/4" ceramic paper gaskets

As will the connecting firebricks.

(Not shown):

Two notches were added to the last course, one for a pressure tap and another one for a thermocouple at the exit.

The ceramic paper gasket was reused. Note the split in the center where the firebrick slab had broken and walked apart.

Thermocouple visible to the left, and in the hole.

Stainless 1/8" tube pressure tap with red silicone hose, ready to install from the rear.

View into the heat exchanger connection.

Adam scale installed.

It can weigh 75 kg with a resolution of 1 g.

Laying out the support stilts for the firebox floor.

A thermocouple is taped to the angle iron to make sure the scale doesn't get too hot.

Too

much heat conducts down through the firebox wall for a useful reading,

and we ended up installing a second thermocouple to monitor the air

temperature itself.

A 1" Skamolex board is set on the stilts.

1/2" gap around the edge.

In order to maneuver the firebrick floor slabs into place, temporary tapcons are installed in the second slab.

We are still working out how to address the 1/8" gap around the edge that allows the floor to float on the scale.

For now, we are using a set of sacrificial ceramic paper strips to make a temporary seal.

Scale head is hooked up via RS-232 serial cable.

We were able to tare the scale, and get a reading of 109 grams when adding the roll of Tyvek tape to the firebox floor.

However,

the scale then generated an error message -- it doesn't like to tare or

zero above a certain starting weight on the scale, which in our case is

about 75 lbs of firebrick slabs.

Tech committee member Crispin

Pemberton-Pigott has a lot experience with these scales, and will

provide us with the custom software he uses to address the scale

directly and bypass the head and the factory configuration.

1/4" steel shims to reduce the air slots.

February 19:

Air slots were reduced approx 50% from 30 sq. in. to 15 sq. in.

See also:

October 31/15: MHA Research Heater construction

December 20/15: Firebox modification

Check out other current

research at Lopez Labs

|