2018 Next Generation Woodstove Design Challenge

on The National Mall, Washington, D.C.

November 9 - 13, 2018

Photo credit: Jim Schalles

The MHA Tech Committee organized a 5 person testing team to send to the

event.

We

brought 3 complete Condar PM sampling systems, and conducted a total of

15 three hour test runs over the course of 5 days. We were

tasked with combustion testing of the thermoelectric stoves. Brookhaven

National Laboratory had responsibility for testing the

automated stoves, with funding help from NYSERDA.

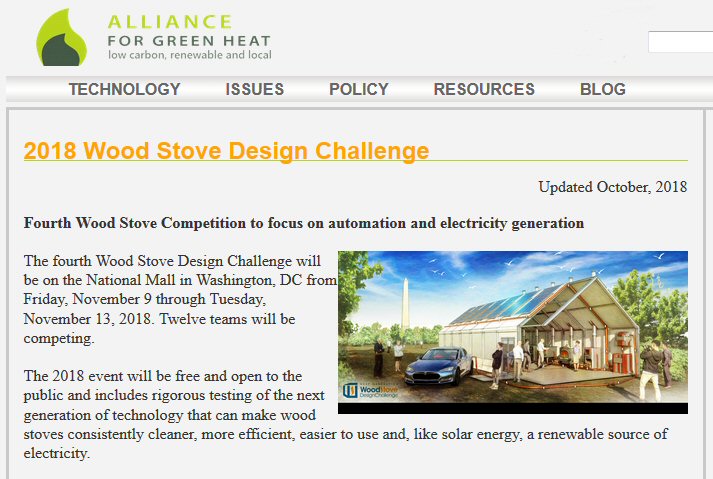

Tesla S being charged by a MES

pellet boiler with a 5kW electric output.

Maine

Energy Systems

AutoPellet boiler with optional Stirling engine generator add-on was a

highlight. They were there by special invitation as a demo, since

boilers were not elible for the competition..

They have a unique

achievement in having brought CHP (combined heat and power) down to a

near-domestic scale on a semi-commercial level. The unit is expensive

at the moment, but they are commercially available in Europe and have

logged many hours on them at client sites. This is the first time I

have seen this combination of user friendly, real world proofed, and

domestic scale electric power output from pellets.

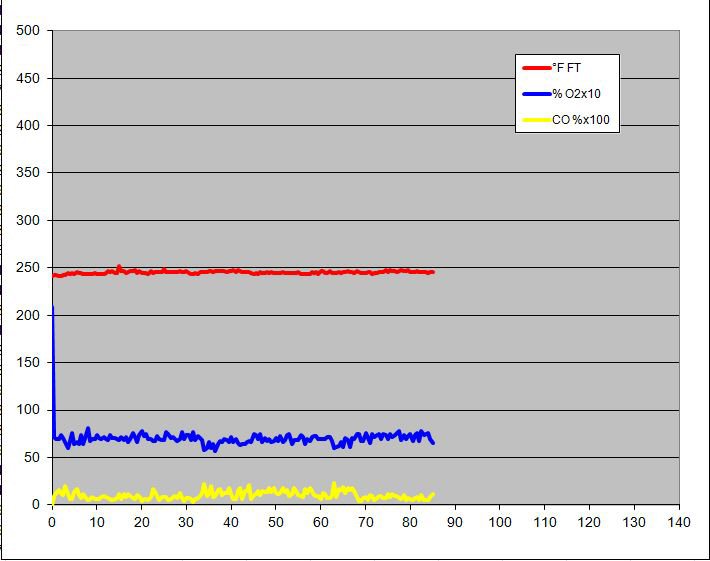

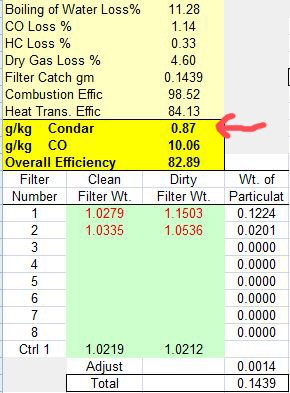

Stack gas analysis graph.

Low stack temperature (250 F), very low oxygen (O2, blue line) and low carbon monoxide (CO)

means high efficiency.

Wittus

automated downdrafting cordwood prototype stove is optimized for

electricity production by using water cooling of the TEG

(thermoelectric) cells. It also has a catalyst in the lower chamber.

View from the rear. On each side is a large bank of water radiators.

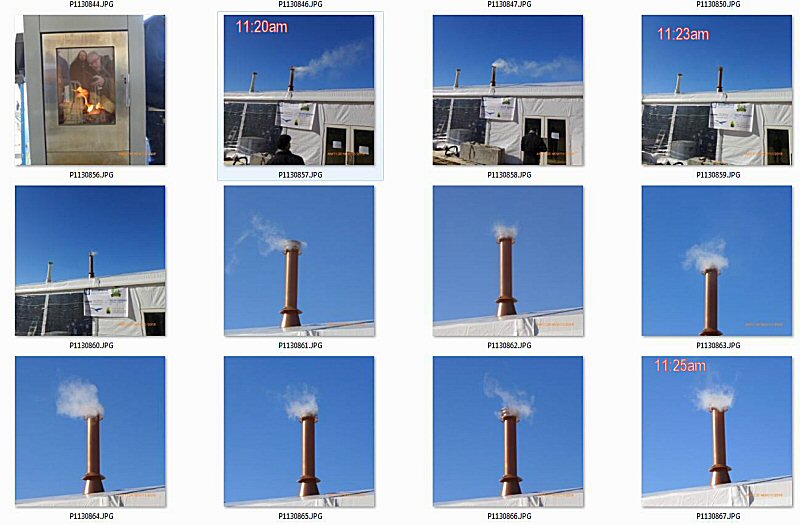

Startup

sequence. Smoke is visible at 11:20 am at startup. By 11:23, no smoke

is visible. Shortly afterwards only steam is coming out of

the

stack, as evidenced by the lack of the plume that is visible on startup.

Segments of the burn had the lowest CO I have ever seen (it actually

got to 0 for a few seconds).

Low stack temperature, low excess air (O2), super high efficiency.

Producing 218 watts of TEG (thermoelectric) power (rear screen).

Stack gas graph. We lost data from minutes 40 to 65. We interpolated

the lost data, as shown by the flat lines.

The 3 reloads are clearly visible as big dips in the blue oxygen line.

This was a trial of a shortened version of the new Integrated

Duty Cycle (IDC) testing protocol under development by

NESCAUM to better simulate real world use in cordwood testing.

Therefore,

the particulate numbers are not directly comparable with EPA laboratory

certification numbers, which one might expect to be lower.

PM and CO are were the same range as we have measured on masonry

heaters with the Austrian

eco-labelled firebox.

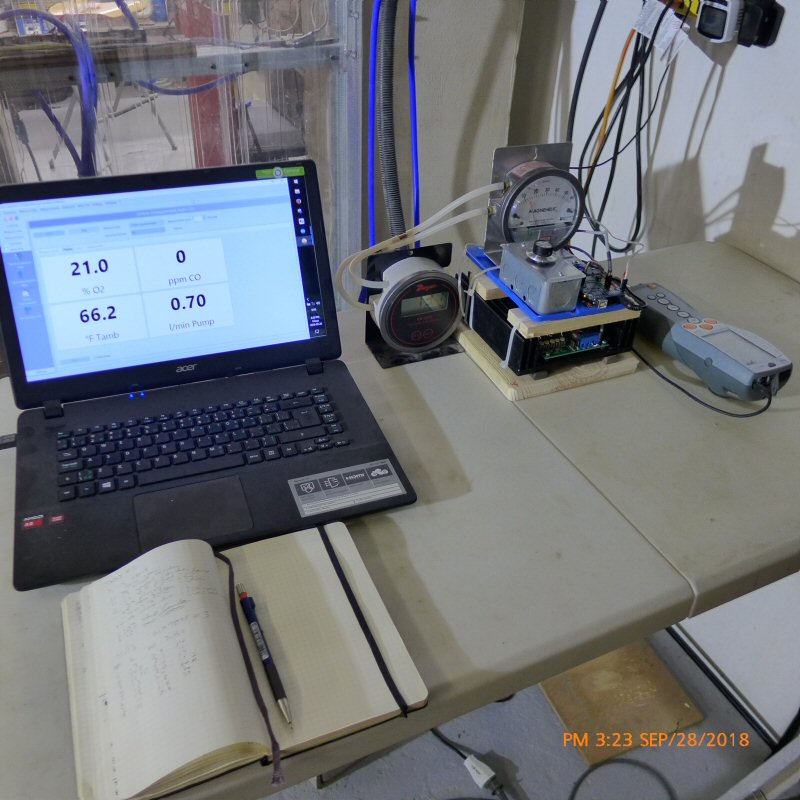

We

spent several months developing and testing this automated controller

for our Condar

portable dilution tunnel PM emissions sampler. It

lessened the work load on our crews to a much easier oversight function

for the equipment, rather than manually having to adjust the

flow

control for the sampler over each 3 hour test period.

Testing the 3 new controllers at the MHA Lab

in Shawville, Quebec, prior to the event.

Arriving

at the tent on The National Mall. Equipment travelled

from sites

in Quebec, Massachusetts, Minnesota, and Maryland. "Some assembly

required"

Photo credit: Kittner for Brookhaven National Lab

Assembling a Tulikivi

demonstration heater, that was used to keep the overnight security

crews warm during some chilly weather. It travelled from the Tulikivi

US distribution distribution warehouse in Charlottesville, VA.

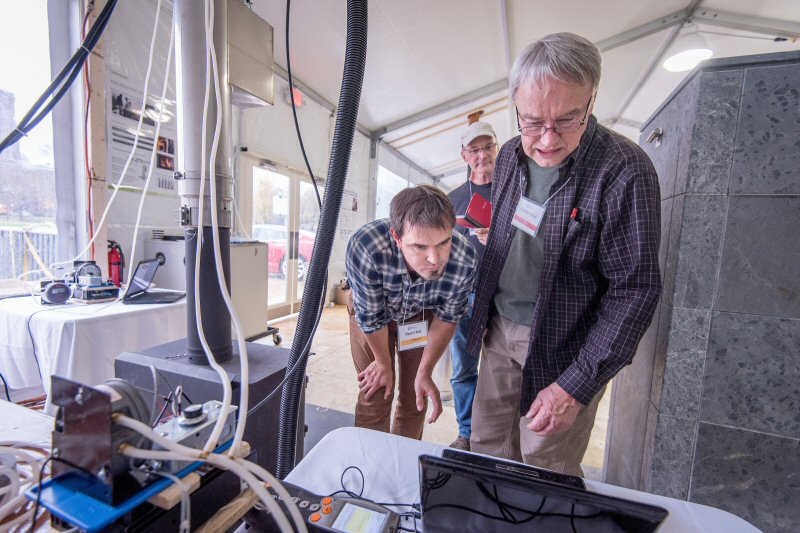

Testing team from Brookhaven National Laboratory setting up their

equipment.

Open to the public and testing in full swing.

Check out this great article about the public's impressions at the event.

Photo credit: Kittner for Brookhaven National Lab

Boris Kukolj, head of Tulikivi North America

Rebecca Trojanowski, test engineer at Brookhaven National Laboratory

Mark Seymour

and Ron Pihl

setting up our equipment on the Kd3

downdrafting thermoelectric stove.

Location of the 3 holes drilled into the stack for:

- Condar

portable PM sampler

- stack pressure reference port

- Testo

330-2 flue gas sampling probe

It

has a very innovative hot side heat exchanger scheme for the TEG's.

After the downdrafting flame finishes combustion and turns the corner,

a thick copper fin that is directly in the gas path is joined to an

aluminum plate that is out of the gas path.

Setting up a demonstation test on the Swiss OekoSolve

electrostatic precipitator.

Demonstration of 30,000 Volt plasma cloud arcing over to a piece of

firewood.

Daniel Jud from Oekosolve checks the Testo readings

Photo credit: Kittner for Brookhaven National Lab

We

ran 2 Condar samplers, switching them on and off at 6 minute intervals,

in synch with the precipitator. The old technology stove

was quite

dirty, as shown by the yellow strong smelling organics on both filters.

The PM reduction on the precipitator "on" filter on the right

was 62%.

Test Report

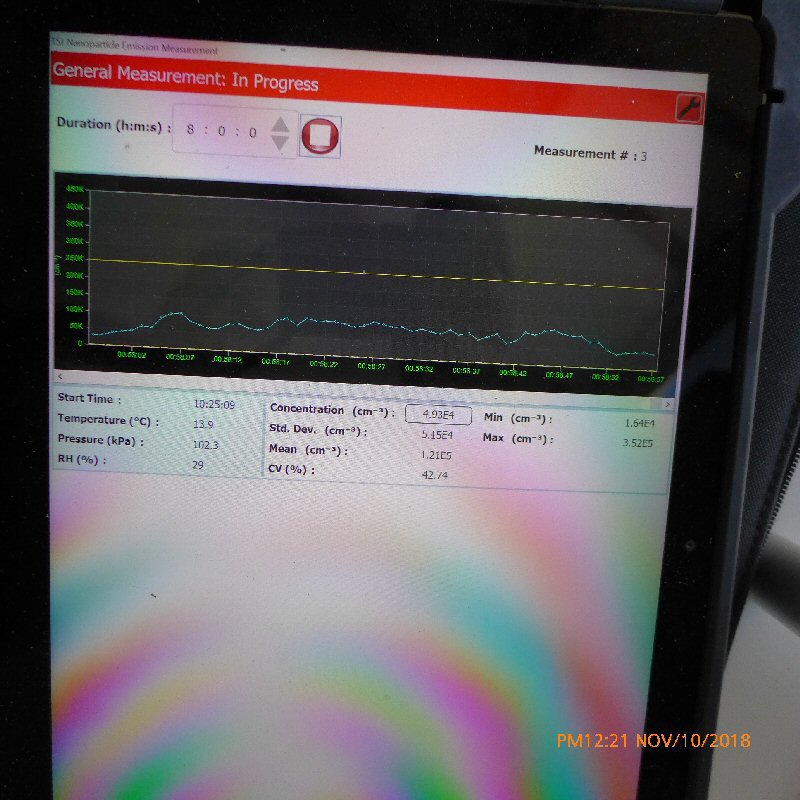

NY

State Dept. of Health brought along a real-time nano particle counter.

It has a cutoff at 1 micron (1/1000 of a millimeter), and counts down

to the nanometer range. It showed a reduction in the 80% range of nano

particles when the precipitator was turned on.

Mark Seymour and Jim

Schalles prep the chimney on a stove with the VcV

(Venturi-Controlled Valve) from New Zealand. It provides automated

primary and secondary air control, without electronics or power

requirements.

A

thin metal disc slides on a rod. Gravity holds the air supply open. As

the stove warms up and draft builds up, the disc is pulled up the rod

by air pressure, and finds a balance point. There is a separate valve

on the primary and secondary air supplies.

Aprovecho

Integrated Stove

A

14' hose connects the Condar to a Kenmore vacuum sitting outside the

tent. The Kenmore is controlled by MHA's new automated Condar

controller.

Ben

Myren did

the fueling on the TE (thermolelectric) stoves. Here he starts up the

prototype rocket stove from Aprovecho. It is designed for a specific

application in China, and has air cooled TEG modules with a large

cooling fin area. It also features an OekoSolve electrostatic

precipitator on the exhaust.

A bit of help was needed from the blue alcohol gel in the cup next to

Ben.

Stack gas analysis graph automatically generated by the Testo EasyHeat data logging software.

Normalized graph in MHA standard format, for comparison purposes with

other tests.

Note the blue O2 line is very close to 20%, indicating very high excess

air on this run.

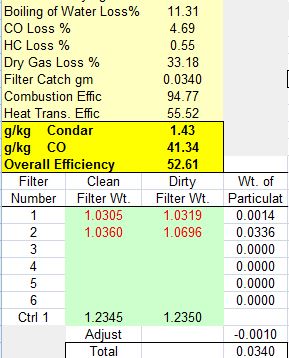

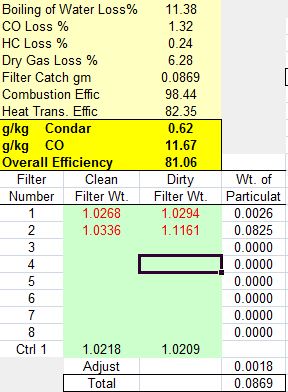

Condar spreadsheet summary. Compare with Run 2, below.

Normalized graph for run #2. The first hour of data was lost due

to a computer glitch.

Condar summary.

The electrostatic precipitator was not functioning in Run 1.

Run 2 had the precipitator operating and has lower PM.

Run 1 had high excess air and high CO, so was a different type of

burn.

SBI entered

a prototype fireplace stove that was completely automated, based on 2

simple sensors - flue temperature and door open/closed. A sophisticated

logic board regulates 2 air control motors to keep the stack

temperature constant and boost the fire on a cold start. Their stove

also had the best fire viewing of all the stoves in the event.

Automated stoves judge Mark Knaebe lights the SBI fireplace stove for a

testing run.

Mark is a United States Forest Service scientist at the Forest Products

Research Laboratory in Madison, Wisconsin.

We

tested the stove simultaneously with Brookhaven for 1 run. However, on

the Saturday morning it was super windy. The Condar controller depends

on measuring chimney pressure accurately, and this was virtually

impossible due to large fluctuations. The PM number was 2X

the

BNL (Brookhaven) number. On two other runs with calmer weather, on the

Wittus and the VcV stoves, we had good agreement.

Thermoelectric expert Fred

Leavitt of Vulcan Energy used commercially available TEGs by

Hi-Z, and adapted the gravity feed Wiseway pellet stove

to get an output up to 130 watts. He won second place in the

thermoelectric category.

Tulikivi's North American head Boris Kukolj discusses masonry heaters

and the NSPS with EPA's Rochelle Boyd.

Jonathan

Male, head of U.S. Department of Energy's (DOE) Bioenergy Technologies

Office, and a lead sponsor of the Challenge, addressing the teams. DOE

was very pleased with the event. Alliance for Green Heat was able to

engage them to now include residential biomass heating in their

programmatic work.

Biomass is the second largest source of renewable energy in the United

States, ahead of solar and wind.

Domestic heating accounts for 25% of biomass use

Rebecca Trojanowski from Brookhaven National Laboratory presented the

First Place award in both categories (automated and thermoelectric) to

the Wittus team, from Denmark and Germany.

I had the pleasure of presenting the Innovation Award at

the closing ceremonies. It went to Stove Builders International (SBI) a

major Canadian Company based in Quebec. They showed a prototype

fireplace stove that was completely automated, based on 2 simple

sensors - flue temperature and door open/closed. A sophisticated logic

board regulates 2 air control motors to keep the stack temperature

constant and boost the fire on a cold start. Their stove also had the

best fire viewing of all the stoves in the event. It also won 2nd place

overall in the automated category.

The "People's Choice" Award went to the 509Fab stove. It

features self feeding pressed logs, and has high efficiency and very

low PM and CO, see Condar summary below:

MHA Testing Team enjoying some stored heat.

Left to right: Ron Pihl, Jim Schalles, Norbert

Senf, Mark Seymour, Boris Kukolj.

|