July, 2009

Description

Results

Comments from Dave Misiuk, July 4

Modifications, July 7

Modifications, July 9

Modifications, July 12, Comments from Alex Chernov

Modifications, July 19

Modifications, July 22

Modifications, July 23

Comments from Peter van den Berg

See also:

John Fisher's Rocket comments from 2007

2009 Wildacres Rocket/Bell hybrid experimental hands on

Rocket Stove Forum (registration required)

The goal was to get a surface temperature map of a large narrow single bell, fired on one end (left) with

a rocket firebox, exhausting at the other end (right) at the bottom.

A flue gas analyzer was run for the last 2.7 hours, to measure oxygen, stack temperature, and carbon monoxide,

and provide a calculated efficiency number. (HHV, or North American definition)

The stove was built, dried out, and data was collected over a 6.5 hour burn of 70 lbs of wood.

Ksenia Chumakova is an architect studying heater construction and design, and made it possible to complete the construction,

and data collection from first test burn within a 3 day schedule.

The bell footprint was laid with a 6.75" deep chamber, to allow for no cuts and a 9" firebrick cap.

Bell is 92" wide and 77" high on the outside.

About 450 firebricks went up in 1 day with 2 masons, including prep, layout, etc.

Ceiling is a 2.5" firebrick cap.

In order to allow easier layout of a measuring grid, and tracking of hairline cracking, the front was

skim coated with lime putty.

Chimney connection at rear side.

Draft was not easy to establish, and required chimney priming with a torch.

Weather was wet and very variable.

Burning scrap to dry out the bricks.

A 6.5 hour burn was conducted the next day, using Beech wood at 17% moisture.

A total of 70 lbs of wood was burned for the actual test.

No hairlining was observed.

Combustion air control.

Gas probe inserted into chimney.

At the rear of the probe is a quick change ceramic particulate filter that cleans the gas for analysis.

Testo 330-2 gas analyzer has many useful features.

It is self-calibrating, and has a USB connection that allows automated control via software on the laptop.

Setup on the rocket stove was about 5 minutes.

Check out the EPA verification testing on the Testo 350 analyzer

A 12 point grid was marked out and measured every 10 minutes for the first 4 hours, and every 30 minutes after that.

Measurement grid locations.

Excel spreadsheet with temperature data.

Temperature Curves

Hypothesis of gas flow, based on surface temperatures.

5 and 8 are the coldest spots.

Gas analyzer raw data, Excel format

Flue gas analysis for the last 2.7 hours

Fueling data, Excel format

fueling rate was around 10 lbs/hr., which seems close to maximum capacity.

Condar spreadsheet.

Particulates were not measured.

An estimated filter catch is plugged in, so that efficiency and CO can be calculated.

Efficiency is low at 44.6%

See discussion with Dave Misiuk, below for suggested modifications

to the design.

July 4/09: email discussion with Dave Misiuk

(this conversation took place before the data was collated, above)

This shows the 6.5" x 4.5" opening from the firebox into the bell.

A piece of refractory insulating board, 6.5" x 12", is added 6" back from the opening.

The previous 6.5" x 4.5" opening was then restored.

Fire started easily. Later, draft was hard to establish and maintain, due to extremely low stack temperatures.

In contrast, the first burn had very high stack temperatures.

Whisps of steam exiting the chimney, slowly. Little or no actual smoke.

Stack temperature was extremely low, around 115F

An operating error with the gas analyzer resulted in loss of gas data.

Very, very different from the first burn.

Excel spreadsheet with temperature data.

Time constraints only allowed a 2:15 hour test, during which 23 pounds of wood were added.

Temperature curves are pasted on top of the previous test, for comparison. Starting temperatures were about 10 degrees higher

than first test.

Note that the hottest previous spots were now the coldest.

Note that the maximum surface temperature, around 155F, is considerably higher than the flue temperature, which was 115F

This demonstrates the excellent heat exchange ability of even a single bell, without channels.

The previous configuration was modified, with the insulating board moved 6" further downstream, or 12"

from the opening.

It was still next to impossible to get draft established. Using kindling only, a torch was required to boost the flue

several times. See flue temperature graph, below. The burn was abandoned.

The spikes represent when a torch was inserted into the chimney flue.

No gas analysis info available do to an error operating the analyzer. Resolved on July 16.

Firebox changes will be tried, next.

Comments from Alex Chernov, July 12, 2009

Firebox was rebuilt with an underfire grate and a bypass damper for startup.

High temperature insulating board was used for a quick build.

Firebrick at bottom controls the air.

Surface temperature graph.

Comparison with surface temperatures from July 7/09

Stack temperatures. (Scroll right)

Compare with fueling data. Total fuel burned was 57.4 lbs

During tailout, the negative spikes are interesting. It seems to indicate gas separation (poor mixing)

Updrafting hot gases are unstable, particularly at low turbulence. See Grimailo's explanation

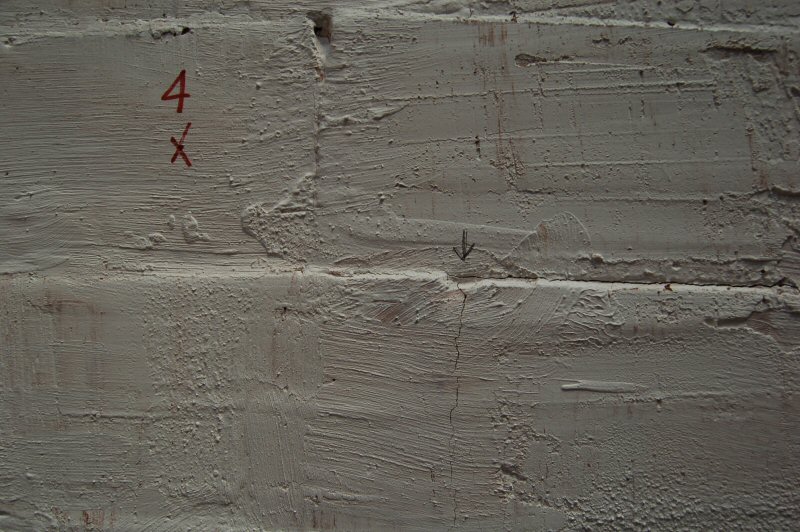

At around the 1 hour mark, a horizontal crack appeared, half way up, in the centre of the heater,

The crack tapered off on either side. Left side shown.

Firebox was rebuilt to take 16" horizontal wood, with a top lid.

Grate at bottom. Note bypass damper on right, open about 1/2".

3.75 lbs of kindling were laid on top of the grate.

The firebox was filled to the top with maple, roughly 3 lb pieces. Total weight of fuel charge was 30 lbs.

Firebox was capped off with insulating board.

Fire was lit with torch (shown above) from below. Very smoky start. Chimney required boost with torch, and then fire took off.

See gas curves, below.

Gas curves.

CO is very high, also smoke.

Note the dramatic change at 63 minutes, when the lid was opened and the wood load was poked.

Stack temperature goes up, oxygen goes down, CO drops drastically, fire stops smoking, efficiency is up.

Testo data in Excel format. Raw data.

Lid was opened at 63 minutes. Fire was smokey, too much space at bottom of pile, around grate. Wood was poked.

See dramatic change in gas curve, above.

Lid was opened near the end, at 95 minutes, for a second poke, and fuel was rearranged on grate. See gas curves.

Efficiency was very good at 73%

Note the high CO loss of 7.2%.

If this were a clean burn, efficiency would have been 80%, near the theoretical maximum of 82%

Particulates is an estimate from an assumed filter weight, no measurement was made.

Surface temperature graph.

Surface temperature data.

The horizontal crack had closed, and was still almost closed at 1 hour (above). It opened up a bit, after that.

The grate was moved towards the front.

The July 19 burn was repeated with the same wood load, 30 lbs.

The pieces were cut somewhat smaller (see fuel photo, below)

Instead of being lit as a batch load, a kindling fire was started, and fuel was added in stages.

Fuel load. 0.7 lbs of kindling on the top right. 30 lbs total.

Previous (July 19) burn used 3.75 lbs kindling, stacked underneath the main load.

Kindling load.

Fire was started, lid was put on, and chimney was boosted with a torch for 2 minutes.

Fire at 30 minutes.

10 lbs of wood had been added by this time.

Firebox started to leak, with some spillage, midway through the burn.

Gas curves.

CO was the highest ever recorded at Lopez Labs.

Fuel would be added, CO would spike.

CO would settle down.

Fuel would be added, CO would spike.

Etc.

Overall efficiency was decent at 69%

However, note the 20% CO loss.

This means that 20% of the energy in the fuel left the stack as unburned CO.

So much for underfire air.

Plan for the next test is to tear down the firebox, and rebuild as a

rocket stove with a heat riser.

This would be the standard rocket configuration, and has not been tested yet.

Front was opened in order to add a heat riser tube.

Note the heat pattern with the existing setup (12" high diverter)

View down the bell. There is an even 3/8" layer of flyash all the way along.

"California Bridge" to back up the riser panels.

Three 12" pieces of insulating board, for a total riser height of 36".

This changed the temperature distribution - the top of the bell got hotter, and the bottom was cooler,

than with with previous setup.

Rocket firebox.

An extra course was added during the burn, so that a lid could be put on to control the air.

2 lbs of kindling plus 28 lbs of maple was burned, for a total of 30 lbs (same as previous burn)

Very interesting burn.

Much easier to start with the riser tube.

Super low stack temperature, incredibly low CO for the middle third of the burn. Very high efficiency.

In the photo above, that is not smoke coming from the chimney. It is

steam. This photo was taken during the cleanest portion of the burn.

Steam was wafting out slowly.

There was not quite enough draft, due to the low stack temperature. Note the flames coming out the top.

Wood is poking out, because of charcoal buildup at bottom of firebox.

A taller riser tube would be interesting to try.

The stack temperature sensor in the Testo probe (upper chimney penetration) failed.

A thermometer was inserted to allow manual stack temperatures to be taken.

Detailed stack temperature records were not taken. An estimated average of 120F was used for

the efficiency calculation.

Gas curves. Solid red line is the estimated average stack temperature.

CO was super low from 28 minutes to 80 minutes.

Some of the lowest CO ever recorded in Lopez Labs testing. CO/CO2 ratio got as low as 0.001

This is in contrast to yesterday's burn, which recorded the highest CO on record at Lopez Labs.

Around the 80 minute mark, the bottom started to plug up with charcoal, and it was harder to add new pieces. This resulted

in quite high CO from 100 minutes to 140 minutes.

As much fuel was added as the firebox would take. The last piece of 30 lbs was only added at 120 minutes.

This contributed to good oxygen numbers, and very high efficiency. The buildup of charcoal at the bottom was a problem.

Testo data - adjusted

Testo data - raw

Condar spreadsheet - efficiency calculation

Surface temperature data

Condar calculations.

Efficiency, at 84%, is at the theoretical limit, due to the very low stack temperature.

The tailout portion of the burn was not included in the efficiency calculation.

However, there is insufficient draft -- the bell heat exchanger is too effective (too large for the firebox size).

PM was not measured, and the PM number shown is a dummy number for calculation purposes.

Hairline crack has completely closed on the cold heater.

It opened back up. The expansion at the very top, due to highest heat, results in

a lifting action at mid-height, in the center 2/3 only.

Comments from Peter van den Berg

July 27/09

Comments from Peter van den Berg

Hi Norbert,

Please find attached two files: one is the Condar spreadsheet, with

the results in average of a recent test run.

The other is a graphic which is the same scale and colours as the last

one from Lopez labs' rocket/bell experiment. Even recalculated to

Fahrenheit. The increment is different, though, mine is noted down

every 2 minutes. That's why it shows as a fluent line.

My results are very much like yours in the sense that the O2 is going

down at the top of a burn and CO is coming down with it. In contrast

with most heaters which got high CO numbers in phase with low O2

numbers. Mine is a bit better at combustion eff. while yours is better

at heat transfer eff. Take notice of the CO level: about half as Lopez

labs' and no spikes at all.

I do think it's necessary to emphasize the fact that my testbed is a

model. The firebox is about 1foot square and 1.5 feet high so it is

small. Primairily, this thing is batch-fed, more or less the same as a

large masonry heater. Not the nearly constant-fed contraption like a

standard rocket stove. Above that, the goal was to create a stove

which should be capable of burning soft wood in a very efficient way.

The plan is to have a larger scale prototype ready in September.

I'll send more data when I have it.

regards, Peter

December 07/09

Comments from Peter van den Berg

View Peter's comments with graphics

Date: Sun, 06 Dec 2009

From: Peter van den Berg <peter(at)pberg.demon.nl>

To: mheat(at)heatkit.com

Subject: rocket/bell project

Hi Norbert,

Last month I've spent some time in order

to fine-tune the rocket/bell. Mainly to be able to get it started

without heating up the stack with a torch.

So far it's going remarkably well. I've prepared graphics of four test

runs, to illustrate the results. I've filled in the Condar spreadsheet

as well. The fourth run, which was the dirtiest had also the lowest

flue temp and is therefore the best with efficiency.

Note the similarities in the graphics, mainly in the CO line. There is

always a small bump in the beginning, then a fairly extensive valley

and a bigger bump at the end. The differences in O2 and stack temp are

caused by fiddling with the air intake. In particular, the ratio

between under air, front air and side air. The hotter the thing gets

the more the emphasis will be on the side air.

The fourth graph do show a sharp peak of carbon monoxide in the startup

phase with an oxygen level less than 5%. In this particulair case the

side-air intake wasn't large enough. As a result, the siphon couldn't

get sufficient air while the temperature was high enough. The interval

of the graph is 5 minutes, while the peak actually lasted much shorter,

something in the order of 2 minutes. It went down really as sharp as it

went up. The conclusion seems to be: the oxygen level has to stay above

5%. When it's getting lower the likelihood of significant CO peaks are

higher.

This fact do limit the maximum efficiency. Two factors play a role in

here: the amount of air that need to be heated and the temperature

that's discharged through the chimney. It seems to be better that the

oxygen is higher than 5%, and during the top of the burn at least 140

degrees Fahrenheit to the chimney is needed. This results in a maximum

yield of 97%, according to the Testo equipment. Some more and the fire

behavior is getting unpredictable.

Above each graph are the averages of that combustion run. Based on the

graphs it's clear that it is not needed necessarily to have a low CO

level in order to achieve high efficiencies. Of course, the quality of

the combustion is better at a low CO level. After a cold start with

outside temperatures below 50 F., a lot of water vapor's escaping the

chimney which simply do resolve within five feet.

Lighting the thing is always the same: stacking the wood to the edge of

the siphon and on top of that a small fire of which the flames

instantly disappearing into the siphon. In that way, it warms up

quickly with an average value of 900 F. in 12 minutes. Opening the door

at the height of the burn is not a good idea. As the siphon is lower

than the top of the door, part of the smoke will come into the room.

At the moment I have no recent graphs of a testrun which has had a

refill. This do provide a complete show with generally very low numbers

of CO and O2. All the wood burns simultaneously, but large jumps in the

different values remain absent. The thing will make a lot of noise, a

kind of dull roar.

The oxygen will go lower than the limit of 5% in about half of the

instances. Without the major peaks in the carbon monoxide readings. The

dangerous point is thus mainly during the cold start, as the side

aeration and the syphon are not hot enough yet.

The mantle of the experimental model will be quite hot after a refill.

The double walled side, in total 5 1/4" refractory castable, has

reached 230 F. at one occasion. At the front, about 4" above the steel

door frame 275 F. during the same run. During such sessions the syphon

will exit between 1560 and 1790 degrees Fahrenheit inside the stove.

What the temperature at the hottest spot will be I don't know, I don't

have a sensor in there. That would also be futile, the sensors I'm

using cannot bear more than 1830 degrees F.

This article is translated from Dutch by google translate, like Eric

Moshier suggested. I sincerely do hope it has become readable English

after extensive editing by me.

regards, Peter

View Peter's comments with graphic

Update March 22, 2015:

Check out this online rocket stove simulator:

This page was updated on

Matrch 22, 2015

This page was created on July 2, 2009