Fireplace Contest FAQ

Go to July 9/09 update on performance testing results

To: "Alex Chernov" <alex_stovemaster(at)yahoo.ca>

. . . "'Norbert Senf'" <mheat(at)heatkit.com>

Subject: Fireplace Design Contest

Date: Wed, 13 Aug 2008

Organization: CCHRC

Gentlemen,

Thank you both for participating in the Fireplace Retrofit Design Contest sponsored by CCHRC.

Each of your entries had extreme merit and I have no doubt that either would work perfectly well for this application.

The designs were similar in size and output and even had a strikingly similar materials list.

Based on this fact, the homeowners were asked to review the designs and select the one they preferred.

They selected Norbert's design.

So congratulations Norbert and thank you Alex.

In my mind, both designs are winners but the homeowner had to choose only one. Alex, with your permission,

I'd like to retain your design and try to find a future retrofit installation for it with another homeowner.

It would give us another opportunity to install and do testing.

Best Regards,

Dave

David Misiuk, P.E.

Cold Climate Housing Research Center

PO Box 82489

1000 Fairbanks Street

Fairbanks, Alaska 99708

(907) 457-3454

(907) 457-3456 (fax)

www.cchrc.org

Existing.

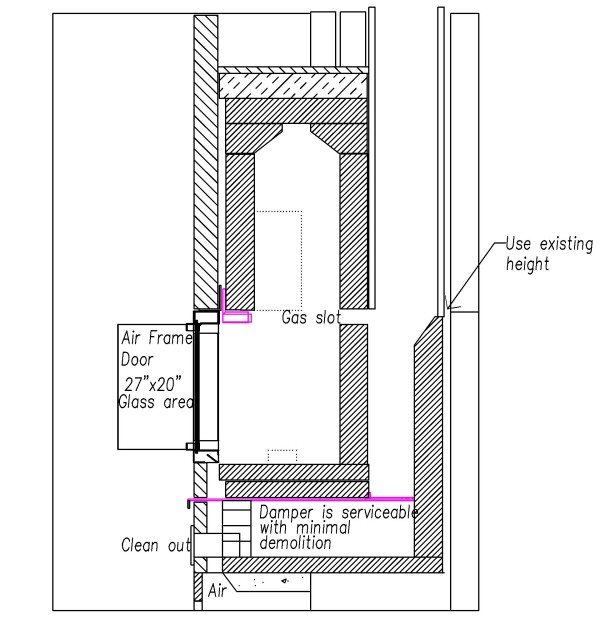

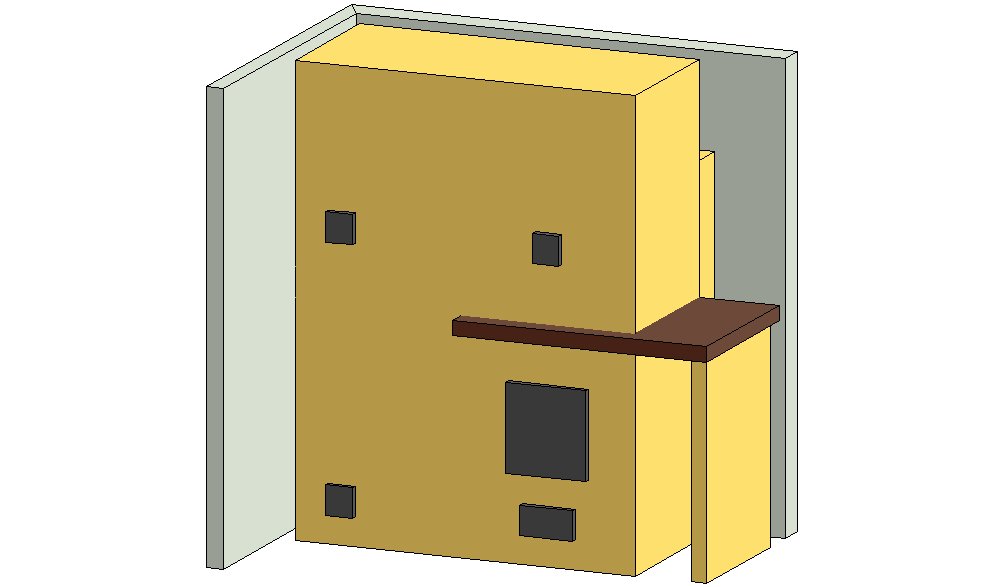

Retrofit - Plan

Isometric

Front Section through firebox (inner bell) and outer bell.

Right section.

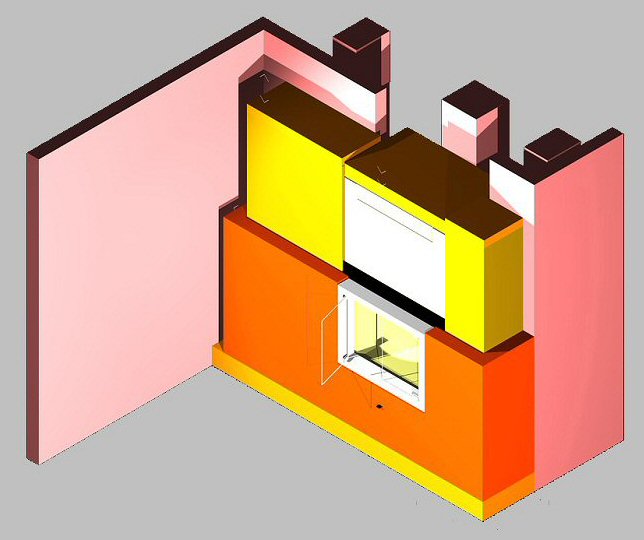

Isometric Rendering.

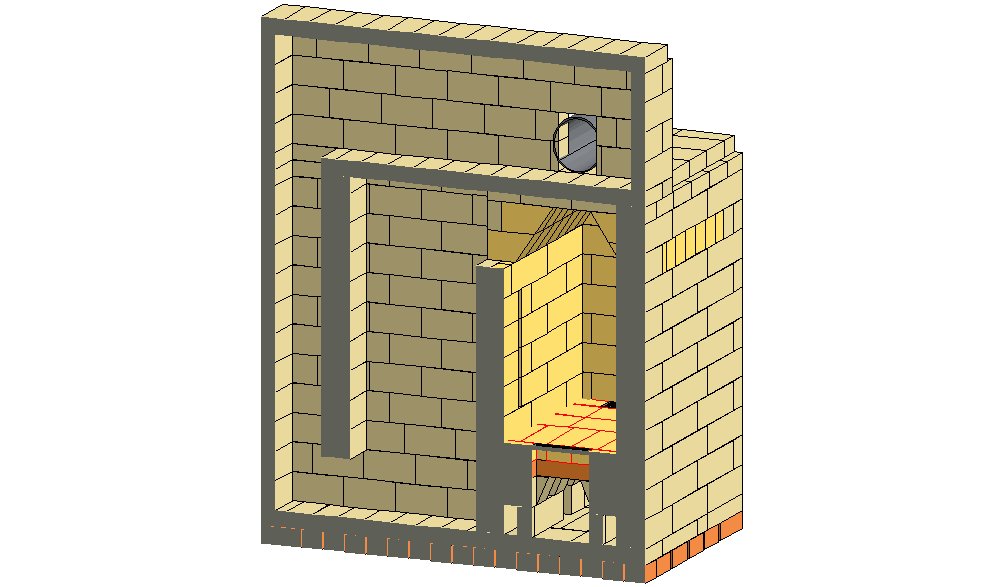

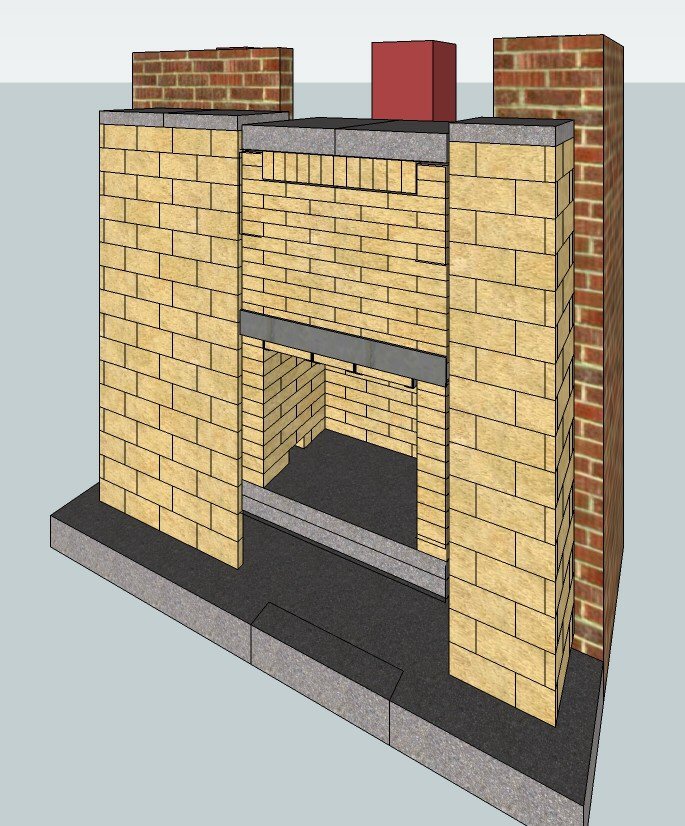

Section drawing of Alex Chernov's double-bell design

Sample facing design, by Alex Chernov

From: "Dave Misiuk" <dave(at)cchrc.org>

To: "'Norbert Senf'" <mheat(at)heatkit.com>

Subject: retrofit

Date: Mon, 27 Oct 2008

Organization: CCHRC

Hi Norbert,

Hope all is going well. Going on week 4 of the fireplace project; haven't even been in the office.

I've attached a photo of our seismic tie concept at the bells.

Castable refractory for compression, all-thread with a bond-breaker for

tension.

Also adds some heat transfer mass.

Weve got a City building inspector who is a structural engineer

checking the work so the piece of paper in the plans portfolio that

says no seismic required for heaters is pretty much out the window.

D

From: "Dave Misiuk" <dave(at)cchrc.org>

To: "'Norbert Senf'" <mheat(at)heatkit.com>

Subject: RE: retrofit

Date: Tue, 28 Oct 2008

Organization: CCHRC

Hi Norbert,

The threaded rod on the seismic ties gets bolted to an external steel

framework of angle and flat bar which is also anchored back to the main

fireplace structure on the sides of the bells. This framework stabilizes the

core and also gives a place to attach brick ties that will go into the rock

facing. I'll send a couple pics when I get the framework installed and while

Dan installs anchors in the face. Seismic is an interesting topic in itself

in this instance given the shallow depth of the bells.

(snip)

We are placing capping slabs today, completing steel framework and starting

to run facing today.

Pic attached.

D

November 15/08:

Comments by Igor Kuznetsov

November 17/08:

From: "Dave Misiuk" <dave(at)cchrc.org>

Hello Igor,

Thank you for the comments.

Your ideas on the structural integrity are interesting because the overall

structural design for this heater does, in fact, include an exterior steel

frame, using steel angles and flat bar, that is anchored back to the main

structure. The steel frame is between the core and facing and is applied

horizontally with no constraint in the vertical direction.

Please see attached photo.

Best Regards,

Dave

From: "Dave Misiuk" <dave(at)cchrc.org>

To: "'Norbert Senf'" <mheat(at)heatkit.com>

Subject: Fireplace Retrofit

Date: Wed, 10 Dec 2008

Hi Norbert,

Good news today. I went to the clients house this morning to install the door, chimney cap and light the

first small curing fire. I burned about 6 lbs of dry birch and everything worked perfectly. The wood lit

easily and quickly, burned very well, and with little smoke. Flue gas is exiting from both bells under the

firebox to chimney as witnessed through the cleanouts at the heater base. Couldn't ask for more so far.

The client has break-in instructions. We will probably go back and fire it with the first full load next week.

We will then begin testing when the heater is up to temp.

Best,

Dave

P.S. Good job!

Initial curing fire, 6 lbs of dry white birch

Date: Thu, 18 Dec 2008

From: Dave Misiuk <misiuk(at)alaska.net>

To: Norbert Senf <mheat(at)heatkit.com>

Subject: Pics

Hi Norbert,

Here's some pics of the last couple week's activities. (snip)

Finished two days of testing at the retrofit house today. Initial

results look very promising although I haven't had time to crunch the

numbers yet.

Birch with bark about 1.6 times the catch of similar run w/no bark.

Just comparing w/the dutch heater runs of < 1 gm/kg, the filter

catch was ~40% more with 2.5 times the wood and same sampling

rate. Stack temperature briefly over 300 F for one run, higher

for the run when we opened the doors to see what would happen.

Combustion air...perhaps lacking as seems to be par for the course here.

Instantaneous efficiency readings during burn generally 83 to 85% except at tail-out.

Hard to say with varying facing rock properties, but large bell side

seemed to run just slightly hotter judging by surface temps; again,

hard to say definitively.

This is a responsive heater; the facing is about 4" thick. Just

the curing fires with a cumulative 65 lbs of wood got the face up to a

good temp. But also, they left the damper open last night and the

heater was still very warm at noon just before our testing.

The homeowners are VERY pleased.

More soon.

Dave

Dan Givens sets the stone facing.

Testing setup.

Testo gas analyzer is on top of the step ladder, with sample line going up over the stone

to the test port in the chimney. Large vacuum line to the Condar dilution tunnel on the right. The red flue liner is visible directly behind

the Condar.

Date: Mon, 9 Mar 2009

Subject: Retrofit

From: Dave Misiuk <dave(at)cchrc.org>

To: Norbert Senf <mheat(at)heatkit.com>

Hi Norbert,

We filmed the final segment of our Fireplace Retrofit video last

week. The homeowners said that the heater exceeds all of their

expectations on many levels: functionality, convenience, aesthetics not

to mention ~20-25% savings in their oil heating bill. They are

extremely pleased and are actively spreading the word. I hope to

have the video for Wildacres; it will be about 45 minutes long.

I would like to put 3D graphics or an animation of the model in the

video to explain the flow path, etc. Would you be willing to

share the original .dwg file to accomplish this?

Dave

(Autocad model by Norbert Senf

Autocad rendering by Dave Misiuk)

Date: Thu, 9 Jul 2009

Subject: fireplace retrofit results

From: Dave Misiuk <dave(at)cchrc.org>

To: Norbert Senf <mheat(at)heatkit.com>

Hi Norbert,

Still have to double check the math, but the first run of the fireplace

retrofit came in at 1.69 g/kg with white birch with no bark, top-down

ignition:

Particulates= 1.69 g/kg

Combustion Eff= 94.9

Heat Transfer Eff= 76.7

Overall Eff= 72.8 (HHV)

The second run was white birch with the bark, top-down start but it

fell from the top and ignited the whole fuel load (oops):

Particulates= 2.46 g/kg

Combustion Eff= 92.3

Heat Transfer Eff= 76.2

Overall Eff= 70.3 (HHV)

Still not bad for a first-pass design, with field modifications based on judgement, I think.

It qualifies for the IRS 75% efficiency by their LHV definition:

http://www.hpba.org/government-affairs/issues-legislation

http://www.irs.gov/pub/irs-drop/n-09-53.pdf

Dave ------------------------------------------------------------------- |