Introduction:

As part of the ASTM standards process, the masonry heater

subcommittee is proposing a standardized fueling protocol that can be

used

for emissions, efficiency and safety testing.

A first step is to qualitatively compare a firing using

the current draft fuel crib with a firing using a typical fuel load, for

several different

sizes of heater.

The first tests were done by Lopez Labs on a 22" Heatkit

heater located near the Lopez facility in Shawville, Quebec.

The fuel was documented, and a photographic record was made

of burns with a draft ASTM crib and a normal load.

The normal load in this case was 8 pieces of sugar maple,

at 14.5% moisture, with a total weight of 65 lbs.

The test pieces for the draft ASTM fuel crib were rough

sawn 4x4's which, unfortunately, got over dried to 8%.

Summary of Results:

|

MIN

UTES

|

Normal Run, 65 lb Sugar Maple

|

ASTM Draft Fuel Crib, 4 x 4 Spruce

|

|

0

|

|

|

|

2

|

|

|

|

4

|

|

|

|

6

|

|

|

|

8

|

|

|

|

10

|

|

|

|

20

|

|

|

|

30

|

|

|

|

40

|

|

|

|

50

|

|

|

|

60

|

|

|

|

70

|

|

|

|

80

|

|

|

|

90

|

|

|

|

100

|

|

|

|

120

|

|

|

|

130

|

|

|

|

140

|

|

|

|

150

|

|

|

|

160

|

|

|

|

170

|

|

|

|

180

|

|

|

|

190

|

|

|

|

200

|

|

|

Fuel Crib Description:

| The fuel pieces are numbered consecutively 1 - 8 as

follows:

First row: - left to right

Second row: - back to front

Third row: - left to right

Fourth row: back to front

The weights were as follows:

1: ___8 lbs

2: ___8 lbs

3: ___6.5 lbs

4: ___10 lbs

5: ___7 lbs

6: ___8.5 lbs

7: ___8 lbs

8: ___9 lbs

Kindling was 1 lb. of poplar, plus 3 double pages of newsprint.

|

See fuel calculation below.

Total weight:

Kindling: 4.7 lb

Main load: 32.3 lb

|

|

|

|

|

|

|

|

|

|

|

|

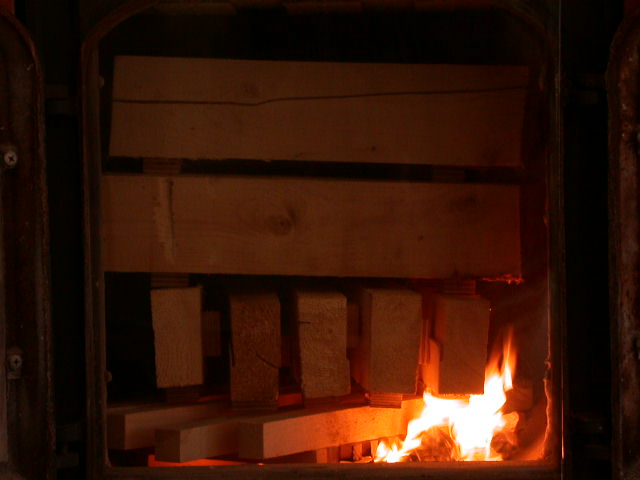

Description for ASTM draft test crib (right):

First tier of newspaper crib (.75" x 1.5" pieces) was

calculated at 8.4" (allowable minimum). Because this heater

has sloped inserts in the sides of the firebox floor, the pieces

did not quite fit on a diagonal, as specified.

Calculated second tier of .75" x 1.5" newspaper crib

requires 22" pieces. In order to make them fit, one piece was

cut as shown, above on the right.

The specified three pieces of crumpled double page newsprint did

not fit in the space provided. One piece was put in, and the other

pieces were put off to the side as shown. Once the crib was stacked,

some of them were shoved underneath, to provide an ignition path.

|

|

| Second kindling tier of 22' pieces of 1.5" x 1.5"

(2" x 2" actual). One piece was cut as shown. |

|

|

First crib tier of 1.5" x 3.5" (2" x 4" actual),

shown with .75" spacers nailed in place.

The spacers on the bottom are an error.

The specification calls for left-to-right orientation. However,

this was judged unstable, and front-to-back orientation was used

instead.

|

|

|

Two tiers of 3.5" x 3.5" (4" x 4" actual),

with .75" spacers.

Each tier is 3 pieces. The specification called for a third tier

of 2 pieces, but these would not fit and were not placed.

If the fuel pieces followed the specification exactly, the top

of the crib would be 2.75" lower, and a top tier would just

fit.

The fuel piece actual length was 16.75". The calculated length

was 15.38"

The main deviation from the specification was the fuel moisture,

which is supposed to be around 20%. The actual moisture was 8% for

the main pieces, and 20% for the kindling tier. The fuel was purchased

green from a local sawyer, and overdried by accident.

|

|

Methodology:

Moisture meter with calibration device.

All wood was taken from the same batch, which has been under cover for

4 years. In order to obtain a moisture value, several sample pieces were

re-split and

the readings taken from a freshly split face.

Weight scale calibration. 2 kg bag of flour reads 4.4 lbs.

Typical piece of fuel. Weight: 8.75 lbs.

Heater doors were replaced with a piece of ceramic glass to allow photographing

an unobstructed view.

In the photo sequence for the standard load, some soot is visible near

the top of the glass in the 10 -30 minute range,

at which point it burns off. This could be avoided by adding a small gap

between the top of the glass and the door

frame to create an air wash.

Photographs were taken with a Nikon Coolpix 995 digital camera set on

a tripod, with a fixed exposure

of 1/60 sec at f-4.6, with an ASA equivalent of 200.

The camera was operated with an M-105 Palm Pilot running the freeware

program "Palmshot".

It turns the Palm Pilot into a time-lapse controller for the camera through

a serial cable connection.

Fuel Crib Calculation:

Note: the above is a screenshot of a fuel crib calculator developed by OMNI-Test

and presented at the Feb. 26/05 ASTM masonry heater task group meeting in

Atlanta.

It supercedes the manual calculation used for the first fuel crib test.

Comments and Conclusions:

This was the first attempt to run the draft protocol.

The fuel crib burned faster than the normal load. This can be partly

attributed to the drier fuel. Therefore, a

repeat test is required in order to eliminate this variable.

Using 4x4 rather than the specified 3.5 x 3.5 fuel did not allow the

full fuel crib to be stacked.

Some kindling stacking issues were highlighted, and should be addressed

by the subcommittee.

Preliminary visual testing such as this should be done on several other

heater models.

See also: Alaska Research Heater

|