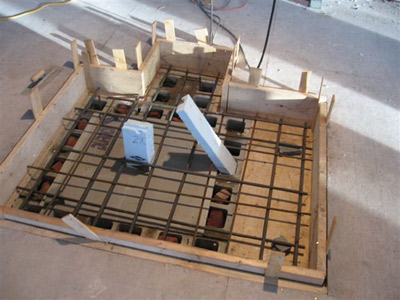

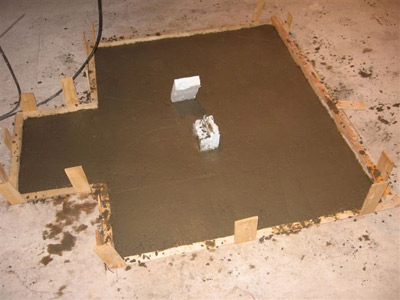

A masonry heater needs a suitable footing and foundation. The images here detail the construction of such a foundation. The function of the foundation is to provide a structurally sound platform at first floor level on which to build.

|

An adequate footing is poured, usually at the same time as the footing for the house walls. |

|

A 4 x 4 foot elevated block foundation is accompanied by a smaller 24 inch by 16 inch rectangle also in block. |

|

The block are layed in type s mortar. |

|

The foundation slab is framed by two inch boards which when removed will leave a 2 inch clearance between the foundation slab and the structure of the floor. |

|

The slab poured and finished. |

|

De-formed the slab is now ready to be worked upon. Once the polystyrene form has been removed a hole is easily cut through the Durock into the void of the foundation. |

See Finished Project

Note: Though in this example the sub floor has also been cut back 2 inches from the foundation slab it is advisable to let the sub floor overhang the 2 inches clearance. This ensures sufficient support for the finished floor. Code requirements are that structural elements of the flooring have 2 inches clearance, not the sub, or finished floor.

|

The sub floor is cut to the exact dimensions of the slab and the framing boards attached to the underside of the sub floor with screws driven in from above. The pencil arrows mark the position of the screws in case their heads become obscured during the pour. |

|

View of the framing boads around the canterlevered portion of the foundation slab. The half inch space behind the boards allows them to be removed easily, and brings the overall clearance to about two and one quarter inches. |

|

The foundation before insertion of the reinforcing rods. The red tape is used to prevent liquid running out of the joints in the form during the pour. |

|

View from below with the framing removed the day afte the pour. There is a two and a quarter inch clearance between the slab and the framing of the floor. |