Voice 819.647.5092 Fax

819.647.6082 mheat@mha-net.org www.heatkit.com RR 5

Shawville Québec J0X 2Y0

![]()

Revised August 4, 2003

Instructions For Finishing Heater

Table of Contents

General........................................................................................................................................................................................... 1

Installing the Sliding Chimney

Damper..................................................................................................................................... 5

Installing the Doors..................................................................................................................................................................... 5

Installing Doors in a Stone

Facing............................................................................................................................................ 7

Installing Bakeoven Door........................................................................................................................................................... 7

Installing Firebox Air and

Outside Air...................................................................................................................................... 8

Template for Oven Arch in

Facing............................................................................................................................................ 9

General

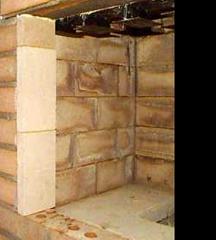

Heater is faced with approximately 5” of masonry.

Typically this is 4” of brick and a 1” mortar slush between the facing and the

core to provide a seal. Bricks are normally laid out to the nearst half brick,

so this gap will vary.

Mortar for facing: Mortar should

be fairly "soft" - masonry cement is O.K. Portland cement/lime mortar

should only be used with a high lime ratio - 1:1:6 portland/lime/sand.

Cavity between back of facing and heater core should

be slushed solid with mortar for

good heat transfer. IMPORTANT:

Do not to puncture the glass mat expansion joint material. Direct contact

between the facing and the core in these areas can result in a cracked facing.

Cleanout doors can simply be mortared in

place. Use the steel bars provided to span openings. They can also be installed

later with silicone.

Chimney

Connection

- Use flue liner; simply make a solid connection between facing and chimney.

Leave expansion joint above liner by laying in a fiberglass cutoffs from heater

wrap, or a piece of cardboard. Liner should have about 8" of solid masonry

above it.

Door Opening: Start door opening 1 - 1.5

courses above firebox floor. If facebricks are cored, fill cores solid around

area of door opening. Steel lintel for facebrick must be set at same height or

slightly higher than firebox lintel to allow firebrick heat shields to slide

underneath.

Rough opening for doors is 18" wide x 20 - 21

½" high. However, the actual opening width in face brickwork is 20

¾". This allows for a 1 ¼" firebrick lining on the door jambs (This

is to keep the facebrick from being exposed in the firebox). See photos on page

4 for lining doorjamb with splits. The 20 ¾" opening usually doesn't work

out too well to the brick bond, so you have to do it carefully.

Angle iron

lintel

above door opening: be sure to provide room at the ends for expansion,

otherwise the facing will crack. Best way is to put a bit of mineral wool or

fiberglass insulation around the ends.

Sliding

Shut-off Damper: Install in chimney high enough

so kids can't reach and you don't hit your head on the handle (6 to 7 ft.). It

should tilt slightly inwards (1/16”) so that any rainwater getting down the

chimney and reaching the damper plate

doesn't run into the room and stain the chimney.

Don't set flue liners directly on damper frame, or

damper will eventually bind. Instead, corbel bricks above damper to make a

ledge for the rest of the liners to sit on. It also helps to mortar in solid

the first 6" of flue liner above damper, so that it can't slip down.

Alternatively, run steel bars above damper for flue

liners to sit on, and then mortar solid

the first 8" of liner above the damper.

Figure 1 - Section through generic heater (no

oven).

Heater Top: (See Figure

1) Run facing past top of core a minimum of 4".

The core will lift up inside the facing when heated,

so it is necessary to install a "crushing

zone" above the core. This is simply 2" of soft vermiculite mix -

6 parts vermiculite to 1 part portand cement. Finish with a 4:1 vemiculite mix, within 1/2" of

top. Finish off with a piece of expanded metal lath (provided) and a 1/2 inch

mortar topping. If heater top shows and needs to be finished in brick, etc.,

raise height of facing accordingly.

Now

is a good time to install the firebrick

splits that face the sides of your

rough door opening. Refer to separate “Door Installation Instructions”,

below. The silicone used needs a day to set before doors are actually installed.

Note expansion

joint at top joint with steel lintel. Gap is stuffed with white ceramic fiber.

Install Ash

Dump: set

it in firebox floor opening.

Install

Firebox Floor Slopes: These are two triangular pieces about 16” long. Set them in

refractory mortar. The space between the front of the floor slopes and the

facing is used to hold the 3” steel bar for the combustion air slot in place,

see next item.

Combustion Air

Slot: Refer

to Figure

7, below. At the front of the firebox floor, you will

see an air slot. Once the facing is on, take the 3” steel bar provided and use

it to form the 1” x 14” combustion air

supply. Air should exit the slot

horizontally, aimed at the back of the firebox. Set the ends of the bar in

place with castable refractory or regular mortar.

Install doors according to separate

instructions provided below.

Chimney: Install a rain cap. Remove

damper sliding plate while building

chimney to avoid mortar droppings forming a mortar bridge at the damper. Be

sure to clean dropped mortar from chimney cleanout before it hardens. Also

check heater cleanouts for mortar droppings from core construction.

Installing the Sliding Chimney Damper

Figure 2

Installing the Doors

These doors are designed for use in contraflow

heaters using the Heat-Kit firebox design.

Rough masonry opening: 20 ¾" wide, 20 - 21 ½

" high. This leaves a 1/4" expansion joint on the sides, once the

door jambs are lined with firebrick splits

Setting

Splits in Door Jambs:

|

Figure 3 |

Install

a day ahead of doors to allow silicone to set.

Splits

come to 1/4” below steel lintel, 2 full plus a small piece.

Set splits as shown, with a solid bead of silicone

along the front edge and dabs of silicone along the back. The gap shown is

exaggerated - press splits against face bricks. Use a thin bead of silicone for

the head joints between the splits, including the bottom joint with the

facebrick. Set the small topmost piece, and stuff topmost joint (at steel

lintel) with ceramic fiber once silicone has set.

Installing

Door

Lay a 2 inch wide by 1/4" thick strip of

mineral wool or ceramic fiber across the bottom of the door opening.

Have a helper hold the doors in place

Note that there are twice as many pre-drilled holes

in the door frame as you need, so that you can pick the best spots to drill

into the face.

Hammer drill 3/16” holes through the splits and into

the facebricks to the depth of the Tapcons. Drill the holes slightly inwards,

to avoid coming too close to the outside face. This also helps to draw the

doors tight to the face.

Switch to a ¼ ” bit and ream out holes in splits.

Using a 5/16" socket and ratchet, screw in the

Tapcons provided. Leave them a little loose.

Using a level across the top of the door frame,

tighten them in the proper sequence to the keep the door frame level.

Pack gap between bricks and door frame (inside

firebox) tightly with ceramic wool.

Install firebrick split heat shields by sliding into

guides on firebox lintel. Slide forward until they touch door frame. The

heatshield bricks on either end require a notch to clear doorjambs.30330

Figure 4. Location of heat shield bricks relative to

door.

Installing Doors in a Stone Facing

With

a stone facing, the easiest way to create the opening for the doors is with a

wooden plug made from 1/2” plywood and

2x4’s.

Note: the doors come packaged in two pieces of

plywood with the required measurements.

|

Figure 5 |

Figure 6 |

Installing Bakeoven Door

The

bakeoven door is held in place with a ¼” Tapcon on either side of the frame.

You will need to drill the frame at the appropriate height to either hit a

brick or a mortar joint, depending on the installation (with dense stone, for

example, you would line the holes up with a mortar joint). No firebrick splits

are required on the doorjambs, as they are with the firebox door. Stuff the

space between the frame and the doorjamb bricks with the white ceramic fiber

supplied.

Firebrick Split Heatshields:

Refer

to Figure

7, below. Note that, after installing the doors, the

firebrick split heat shields are shortened and rounded at the back to provide

smoother airflow at the rear edge.

Installing Firebox Air and Outside Air

Figure 7

An insulated flex duct is connected from the 6” thimble to a screened grill, preferably on the windward side of the house. If your local code does not require outside air, you can skip this step. It will not affect performance of the heater.

Figure 8 Air Bar is positioned and held in place with mortar at the ends. Refer to Figure 7 for dimensions.

Template for Oven Arch in Facing

Figure 9