Community Ovens in the Massif de Megal

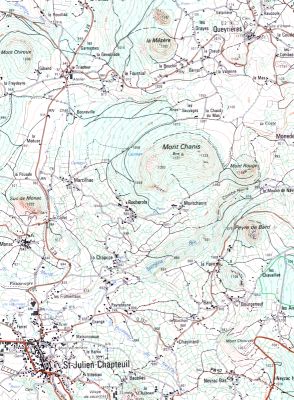

Below are detailed the community ovens of 4 hamlets on the slopes of Mount Chenis in the Massif de Megal,

Haute Loire. Also shown for comparison are ovens in several other hamlets in the immediate area.

Many of the ovens have not been regularly used in recent years, and some of the hamlets partially deserted.

Information specific to each oven is unfortunately lacking. The limited notes below

were acquired by speaking to the few residents of the hamlets old enough to remember

the days of regular communal baking.

The landscape of Auvergne has been characterised by an extended period of volcanism,

the last events of which occurred as recently as 10 000 years ago.

Interesting is the local vernacular seen in the form of the bake houses, which are built from irregular pieces of basalt and Trachyte.

The roofs of the bake house are of Phonolite, an acid lava rock which cleaves easily in to plaques.

Being readily available, the occurrence of phonolithe has contributed greatly to the distinctive

form of the bake houses and their chimneys. These plaques of dressed phonolithe when used as

a roofing material are called Lauzes.

The dressed stones framing the door and window openings of the bake houses are usually arkose.

The vaulted bake chambers of all the ovens were originally from Tuf, a rock taken from the plugs of certain ancient volcanoes. Tuf in French or Trifu, in patois, is formed when magma picks up granular contaminants from the chimney wall, as it is forced up through the chimney, forming relatively light agglomerate.

The moduls that make up the voussoir and keys of the bake chambers were quarried, dressed,

and assembled by the original occupants of the hamlets, who besides being farmers, were also masons, and carpenters.

The bake houses were built by the community, and are usually located next to L'Assembly, or communal assembly hall.

According to an amateur historian the ovens are at least 200 years old. At this time the area was not under direct control of the state but was administered by a local seigneurie or lord. It is not known which, but some of the ovens were built by the seigneurie in return for a perpetual share of the grain harvest, a portion of which was passed on to The Crown.

As times have changed and many outsiders moved into the hamlets, the habits of communal living have dissipated.

This is directly reflected by the ovens, which if at all, are now fired only during the annual village festival.

At one time though, communal interaction in all aspects of living was a survival necessity which the local population well understood.

In general the ovens are maintained in reasonable condition, appreciated by the residents as a symbol of the hamlets heritage.

The largest single factor in the demise of communal baking in the area was the

establishment of artisanal bakeries in the nearby town of St-Julien-Capteuil.

Prior to this, the residents of the hamlets on Mount Chenis would take their grain down

to La Chapuze to be milled, which being located on the fast flowing Sumene, was the nearest

hamlet with a mill.

Bread would be baked in the community ovens every three weeks in summer and every fortnight in winter.

Once the bakeries were established in St-Julien the bakers would buy the grain from

the hamlets and have it milled.

The residents of the hamlets having the option of fresh baked bread daily, and

being freed from the laborious task of making dough and firing a large oven,

gradually lost the habit of baking their own bread. This period of transition

occurred from the 1930s until the early1950s, when regular use of the communal

ovens was completely abandoned.

La Chapuze Altitude 850 m

Marcilhac Altitude 950 m

Rocherols Altitude 1000m

According to a 77 year old resident of Rocherols, the tuf used in the vaults of the ovens in Marsilhac, Rocherols and Mountchenis was quarried on Mount Rouge, which is 1kmEast of Montchenis, the highest of the three hamlets located on the slopes of Mount Chenis. A small mountain by comparison mount Rouge is accessible from Monchenis by a track running over relatively flat ground. The point at which the tuf was extracted from this trachyte suc is no longer known, and there is no obvious evidence of quarrying, that could be found, around the base of the mountain.

Montchenis Altitude 1050 m

Aupinhac Altitude 830 m

Montferrat Altitude 850 m

Les Granges Altitude 660 m

Le Pertuis

Firing Of An Oven

The following series of images show the firing of a residential bread oven in the municipality St-Julien –Chapteuil. Haute Loire. The oven is of the same traditional construction as the ovens detailed in the notes above, the bake chamber being of Tuf. The oven was pre-heated with a priming fire the day before baking in order to reduce firing time.

Marcus Flynn

2008