Project Notes Gironde

These images and notes were taken during the construction of a contra-flow heater in Aquitaine. Only some specific points in the project are outlined.

MATERIALS

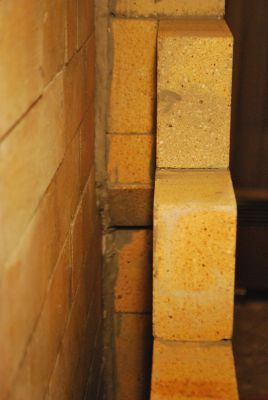

REFRACTORY BRICK

BONY B40N

REFRACTORY MORTER

REFRACOL 8

COMMON BRICK

WOOD FIRED ARTISANAL

COMON MORTER

TYPE N

The heater would be built in to a load bearing wall having approximately two thirds of its depth protruding into the living room, and one third into the hallway and stairwell.

A course of clay tile have been layed to gain some height, (as opposed to a course of thicker clay brick) and because they were available. The tiles also form a clay base for the bottom of the smoke path in the manifolds.

A course of clay tile have been layed to gain some height, (as opposed to a course of thicker clay brick) and because they were available. The tiles also form a clay base for the bottom of the smoke path in the manifolds.

The rear manifold wall has two openings for manifold access. The wall is built with right angle corners on each end, to add stability around the openings.

These portions of the core could be built in common clay brick, layed in type N mortar or refractory mortar. Refractory brick of any kind are unnecessary.

The following 4 images illustrate the cutting of the corners in the sloped floor of the fire box.

This procedure is described in detail in the article by Jean-luc Rosenlenet

This procedure is described in detail in the article by Jean-luc Rosenlenet

The core is set back by 6cm, 5 courses above the fire box lintel. This is only to allow for an aesthetic variation in the facing. The front face of the heater, above the fire box loading openings arch will be recessed by 6 cm. This is an attempt to make the heater less intrusive in what is a relatively high, narrow, room.

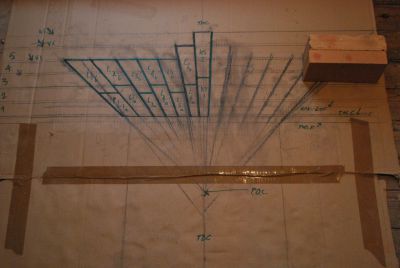

The template for the jack arch. The arch will have 12 split voussoirs and a split key. The brick used for the arch are 5cm thick and were ordered specially for the arch work as the facing brick of 4cm. would have been too thin.

TDC

Top dead center

POC

Point of convergence

Apx LOF

Approximate limit of flange.

TOLC

Top of last course

The assembled arch. Once layed up the space left for the key was too wide for the thickness of even the 5 cm brick. The bed of a brick was used as the face for the upper piece of the key, allowing the key to be slightly wider, at the top, than the thickness of a brick.

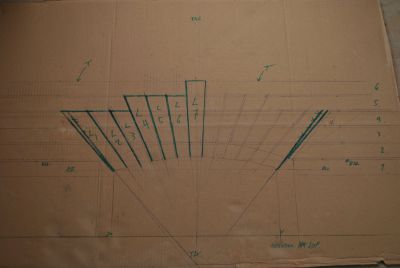

The template for the arch over the oven loading opening.

TDC

Top dead center

ASL

Actual springing line

VSL

Visual Springing Line

Apx LOF

Approximate limit of flange.

Good strong brick ( marked with an X) that were deliberately layed into the opening, are selected to hold the concrete screws. When working with an unfamiliar brick it is prudent to bare the attachment of the hardware in mind.

Test holes were drilled in to a lighter, under fired brick, and it split both during drilling and insertion of a screw.

When drilling the holes in the door frame the drill, after piercing the frame, should be rocked perpendicular to the frame to create an ovoid hole which will provide less resistance to a screw that will be driven at an 80 degree angle into the surface of the brick.

When drilling the holes in the brick the size of the opening and length of the drill will prevent the drilling of perpendicular holes. This is useful as perpendicular holes are not desired. If the the holes are drilled at about an 80 degree angle, then as the screws are tightened the door frame will be pulled onto the face of the surrounding masonry around the opening, as the screws are tightened.

When drilling the holes in the brick the size of the opening and length of the drill will prevent the drilling of perpendicular holes. This is useful as perpendicular holes are not desired. If the the holes are drilled at about an 80 degree angle, then as the screws are tightened the door frame will be pulled onto the face of the surrounding masonry around the opening, as the screws are tightened.

The flue tile with cut outs for the stoves connection, and access opening. The tile has been grouted with concrete.

There were only ever 4 black and white decorative tiles on the whole floor of uni-coloured black and white tiles.

The rear face of the heater protrudes into the hall way between the living room, dining room and kitchen. A full course and half course of black tile have been incorporated into the facing.

Marcus Flynn

2010