Refractory Core Construction Notes 2008

The article illustrates the introduction of a masonry baffle into the lower portion of the

normally straight wall of the fire tube behind the ovens rear slab.

The addition of a baffle at this location is in my opinion a considerable amelioration to the original design.

Also illustrated is the cross bonding of the courses in the corbelled ceiling of the fire box as it rises

opposite the baffle - and the protection of the ovens back slab from thermal shock.

Note also the exposed edge of the ovens rear slab.

Copyright Pyromasse © 2008, all rights reserved.

Copyright Pyromasse © 2008, all rights reserved.

The diagrams show the addition of the corbelled baffle in the wall opposite the corbelled fire box ceiling.

The drag from the corbelled courses on the baffle cause additional turbulence and so mixing,

and promotion of secondary ignition. If the wall is straight the passage of the smoke over

it is much faster and almost un influenced by turbulence.

This becomes more of a consideration when the oven opens in to the front face above the fire box opening,

as a large proportion of gases are blown up to the back of the fire box and then drawn straight up the fire tube.

With the oven opening in the rear face the smoke air and flame are blown up towards the back of the fire

box and forced to pass over the corbelled fire box ceiling, before entering the fire tube.

The corbelled courses of the baffle also add more mass and greater wall thickness to an area of intense heat. With the oven opening in the rear face, this added mass relieves some of the immediate heat stress from the archwork of the facing over the fire box opening.

The flame rising up against a straight wall will always have a layer of, insulating, air between it and the wall as it rises. The baffle will cause the flame to be thrown back and grip the wall as it rises, increasing heat transfer.

The corbelled courses of the baffle raise the total interior surface area by the area of their exposed horizontal surfaces. Heat transfer on the upper surfaces must though be impeded by the rapid accumulation of Fly ash during each fire.

The baffle causes a narrowing of the smoke path to a throat, just before the fire tube, reducing the amount of partially mixed gases entering the tube.

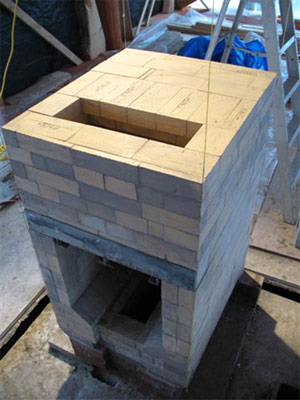

The following images are all of the same project, with the oven opening in the rear face of the core.

The brick are Vesuvius, France Non Spall. layed in Mount Savages Super High Mull.

Castable: Mount savages Heatcrete 24ESC.

Two corbelled courses of the fire box ceiling have been layed.

Note: At this point it is not unreasonable to lay of-cuts behind the corbel.

Note that the course above the last corbelled course of the fire box ceiling (right) is counter corbelled by three quarters of an inch. This is to cause turbulence, and to keep the ovens back slab, which will rest on the course above this, back out of the direct path of the flame.

Setting the ovens back slab forward slightly is an attempt at reducing thermal shock on the slab. This makes the oven less deep and the fire tube deeper.

The core illustrated here is high by comparison. When building within a height restriction, keeping the ovens back slab away from the flame is more of a challenge.

Symmetrical corbels from front and rear of the fire box arrive at a relatively wide throat. The half brick pillars in the centre of the front and rear walls of the chamber reduce the span of the capping slabs, add mass, and surface area, and form a distinct separation between the two halves of the upper chamber (though this would only be relevant were the chimney located on the side). These columbs are stacked and not tied in to the walls against which they rest, relying on the weight of the slabs above to keep them in place.

Note: This core is also comparatively high.

Marcus Flynn

2008