The following account is of two projects undertaken by Pyromasse In Auvergne during the summer of 2003. Both contracts came from the pyromasse web site, one being in La Creuse the other in the neighbouring department of Puy de Dôme.

Creuse. The location of the project was a small hamlet in the extreme south east of the department. There are 7 dwellings in the hamlet, the heater being built in the house of its former wealthiest resident, Msr Parrie. The granite residence that dates from the 1840's, had stood derelict for the last 25 years, and was now undergoing complete renovation.

See also: Technical Documents PDF Index

The barns gable with cross made from wine bottles, a Creuse tradition.

Decorative Stencil

Plans of a house

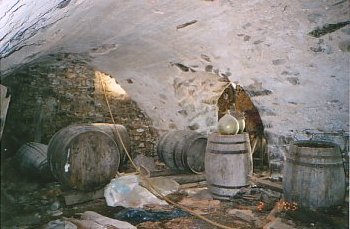

Traditional ovens

Old Masonry Tools

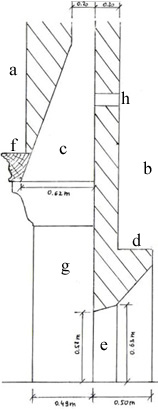

The object of the project was to build a Finnish style contra-flow heater into the large recess of the original "Walk in " granite fireplace, avoiding the heaters protrusion in to the main living area as much as possible. Consequently the heater was placed in the centre of the existing fireplace 2 inches from its rear wall, directly beneath the chimney.(The 2 inch space allows thermo-siphoning of heat of the rear face of the heater.)

Location:

b) Small room behind living room.

c) Smoke hood and flue of walk in fire place

d) false fire place surround in the small room.

e) Cast iron plaque in rear wall of fire place.

f) Oak mantle.

g) Granite columns and arms supporting the upper structure.

h) A hole through the wall once allowed a wood stove located in the rear room, to vent into the flue of the walk-in fire place.

Designe J-M

Materials:

The refractory materials were shipped from Fayol SA. in Tain l'Hermitage. The castings from Upo in Finland. As a facing brick there was almost no choice. The bricks used are sold as a semi -refractory brick. Dense, solid and of modular format, they were ideal for facing a masonry heater. All other materials were acquired locally, the shut off damper being custom made in the next village.

Facing:

Though the house was built in the nineteenth century the brick façade of the heater would follow art deco lines. Local granite was used to make the vousars of the jack arc opening, to integrate the new brick heater with the old granite fireplace. The whole department is granite and so it was appropriate to use it as much as possible in the design of the façade.

This textured and flattened the surface of the weathered stones. Note the cardboard template for one of the vousars, on the ground at left.

See Also Portfolio "Creuse"

Puy de Dôme

The second project was in an even smaller hamlet ( having only

three houses ) 1000 m above sea level in the vicinity of Besse,

Puey de Dome.

The clients were living in a pre-revolution farm house and were

in the process of restoring the adjoined barn. It was in the barn

that a Finnish style heater was built.

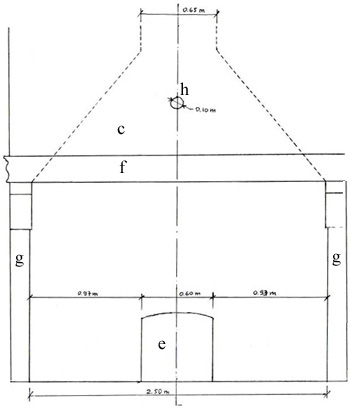

The farm house seen from the rear. Originally the house had an oven built into one of its outside walls. The long collapsed oven and protective housing were outside the house, the loading opening and avaloir ( still intact ) opened into the kitchen through the exterior wall. The residence is dated 1765 on the door lintel.

The materials were of identical quality and origin to those

used in Creuse. Local refractory products were available, though

I chose to use materials I knew from Fayol sa in Tain L'hermitage

and Upo of lappi. The Co-ordination and back up for the upo

castings was by Maine Wood Heat Co.

Due to a lack of choice the same facing brick used on the Creuse

Project, was employed here.

The refractory core was built on an elevated concrete block

foundation. The chimney being located on the right hand side of

the heater.

The object of the project was to build and face the core along

with 9 feet of chimney, in two weeks. To break up the stark

contrast of the bricks them selves the jack arch over the fire

box door was made from Volvic, a local, soft volcanic rock.

See Also Portfolio "Puys de Dome #1"

Marcus Flynn

Montreal QC.